| |

TM 10-3930-671-24

Preliminary Checks

For

safety

when

checking

or

removing

battery

connections, always disconnect the negative battery

cable at the engine ground connection first.

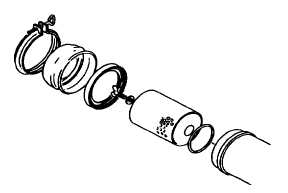

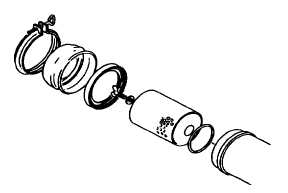

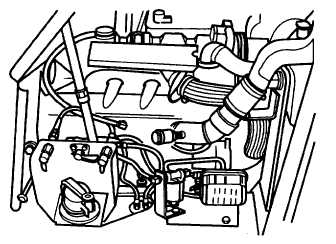

Be careful when inspecting or replacing the air filter

element to prevent dirt from entering the engine air

intake housing. Damage to engine may result.

NOTE

The following quick, simple checks should always be

made to make sure that basic and easy to find troubles

are not the cause of poor engine performance. Once you

have eliminated these items you can check into the other

possible causes of poor engine performance.

The following preliminary tests show whether the basic

engine systems are functioning and that charging and

cranking systems are okay or in need of repair. Remove

the voltmeter after these tests are made.

Blow-by, circulated into intake manifold, maintains

crankcase pressure within a narrow range regardless of

operating speed or load. Servicing of the PCV system is

usually confined to cleaning PCV orifice and/or valve

along with cleaning the air inlet, where applicable. All

connections must be air tight.

1.

Check engine oil and coolant levels.

2.

Check engine air filter. A clogged filter will cause

engine power loss. Replace, as needed.

3.

Check air intake tubes for signs of filter leakage.

4.

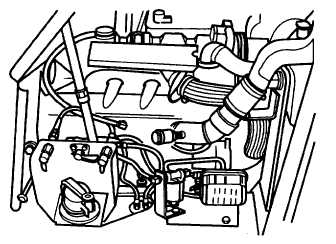

Check crankcase breather system to be sure it is

functioning correctly. Check the following and, if

necessary, clean or replace faulty parts.

a)

Breather hoses for damage, cracks, and

clogging.

b)

Rocker cover and intake manifold fitting

holes for clogging.

c)

Repair or replace as required.

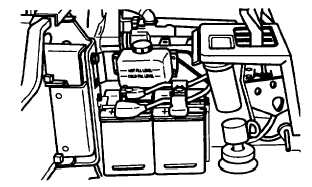

5.

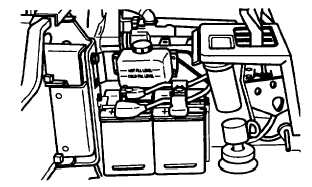

Check battery for damage and cleanliness of

terminals. Remove the boot covers to expose

terminal connections. Clean battery terminals

and cable connections if they are dirty and

corroded.

Check

battery

terminal

cable

connections for tightness. Replace boots over

terminals after inspection. If necessary, wash

battery with a mild solution of baking soda and

water. First, make sure that cell vent caps are

tight to ensure that soda solution does not

contaminate battery electrolyte.

F-74

|