| |

TM 10-3930-671-24

3-31.

GENERAL HYDRAULIC PIPING REPLACEMENT.

a.

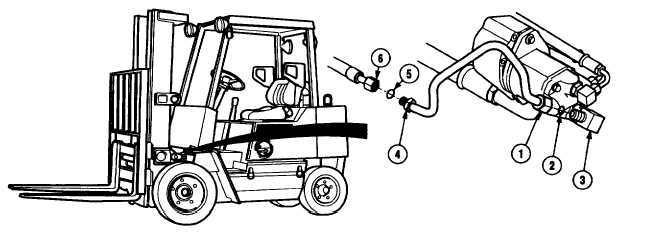

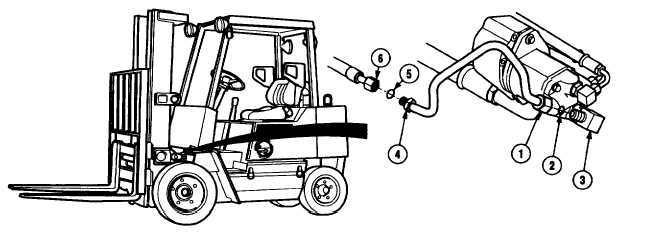

Removal. The truck is equipped with rigid hydraulic pipe connections. The following procedures cover

removal and installation of these fittings. These procedures will apply to all rigid piping installed on truck.

WARNING

Hydraulic fluid is slippery and can cause personal injury when spilled on a floor or other smooth

surface. Precautions should be taken to avoid any spillage and to clean up any spills when they

occur.

NOTE

•

The subparagraphs show a typical connection and fittings on truck.

•

This procedure is for reference only to show piping replacement procedures used on

truck. It will never be necessary to remove all hydraulic piping at one time. Individual

procedures will indicate the area where is to be removed and installed.

•

Some hydraulic piping will have straps holding it to a stable frame part to reduce vibration

during operation.

•

Some hydraulic pipe fittings will have a preformed packing. Preformed packings should

be replaced whenever corresponding fitting is removed.

•

Place suitable container with a 1 gallon (3.8 liters) capacity under any hydraulic pipe that is

being disconnected to catch spilling hydraulic fluid.

(1)

With the forklift turned OFF, operate hydraulic control levers to relieve all pressure from the hydraulic system.

(2)

Remove floor panel from forklift (Para 3-36).

(3)

Remove hydraulic pipe fitting (1) and seal (2) from fitting (3).

(4)

Remove hydraulic pipe fitting (4) and seal (5) from hose (6).

3-88

|