| |

TM10-3930-671-10

Planned Maintenance and Lubrication

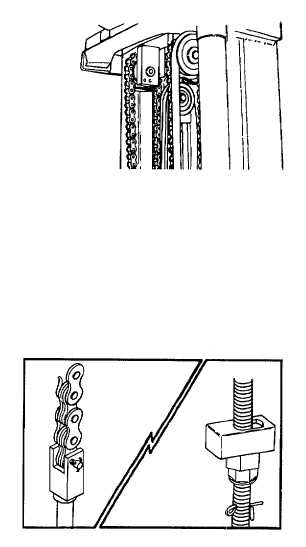

Lift Chain Lubrication

Lift chain lubrication is an important part of your

maintenance program. The lift chains operate under

heavy loading and will function more safely and have

longer lift if they are regularly and correctly lubricated.

Clark chain lubricant is recommended. It is easily

sprayed on and provides superior lubrication.

Lift Chain Adjustment

The lift chains are correctly adjusted if the lower fork

carriage

rollers

reach

their

end

(lowest)

position

approximately 0.50 inch (13 mm) from the lower edge of

the inner rail. This also positions the bottom of the forks

the same (equal) distance above the floor. To check this

dimension, raise the carriage to a height that exposes

several inches of the inner rail at the roller path. Apply a

layer of grease to the roller path on the inner rail. Lower

the carriage and pick up a rated capacity load, (tilt the

upright back slightly) and raise the load until the carriage

rollers have passed over the greased area. Lower the

load completely and remove the load from the forks.

Raise the carriage again to expose the inner rail. You

can now check the roller path pattern in the grease and

determine the correct adjustment of the chains.

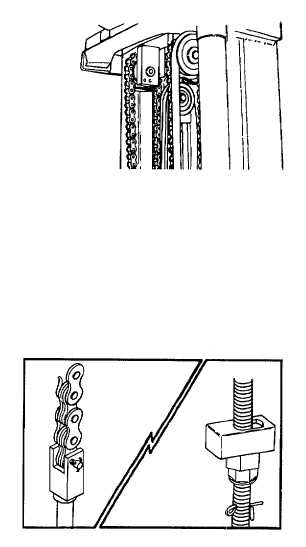

The lift chains can be adjusted by loosening or tightening

the chain anchor nuts.

NOTE

If the chains show slack due to an increase in length,

they should be measured for wear. When the chains

have stretched by wear more than 3% of their

original length, they are not safe and must be

replaced.

E-104

|