| |

TM 10-3930-669-34

8-9.

FLYWHEEL REPLACEMENT/REPAIR.

This task covers:

a.

Removal

c.

Cleaning/Inspection

e.

Installation

b.

Disassembly

d.

Assembly

INITIAL SETUP

Tools and Special Tools

Personnel Required

Tool Kit, General Mechanic’s: Automotive

Two

(Item 1, Appendix E)

Retainer (Item 13, Appendix E)

Equipment Condition

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

Drive plate and torque converter removed

(Item 5, Appendix E)

(Para 8-8)

Starter removed (TM 10-3930-669-20)

Materials/Parts

Rags, Wiping (Item 19, Appendix B)

Solvent, Dry-cleaning (Item 20, Appendix B)

a.

Removal.

(1)

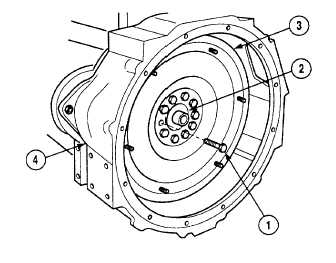

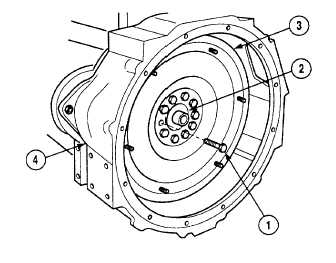

Remove six often screws (1) from crankshaft (2)

and flywheel (3).

(2)

Loosen remaining four screws (1) until head of

screw (1) is .25 in. (6 mm) from flywheel (3).

(3)

Using a soft-faced mallet, strike flywheel (3)

through adapter housing (4) starter hole to

loosen flywheel from crankshaft (2). Rock

flywheel, if necessary, until it is loose from

crankshaft.

WARNING

Flywheel weighs 63 lbs.

(29 kg). Use the aid of an assistant

when removing flywheel or injury to

personnel can result.

(4)

With the aid of an assistant, support flywheel (3)

with a bar and remove four screws (1) and

flywheel from crankshaft (2).

8-68

|