| |

TM 10-3930-669-34

(8)

Using dial indicator, measure the float of the

crankshaft.

NOTE

If

crankshaft

end

float

requires

additional

shimming,

repeat

replacement procedures.

(9)

Crankshaft end float is 0.006 to 0.012 in. (0.15-

0.314 mm). Add or subtract shims as required.

(10)

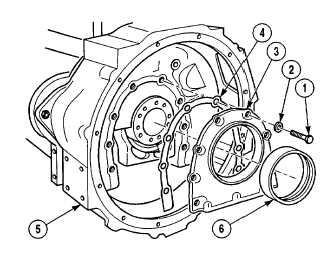

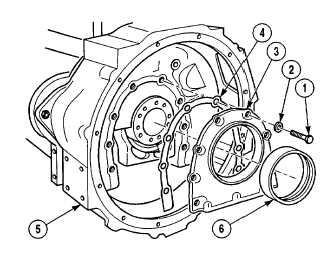

Press seal (6) into cover (3).

(11)

Install gasket (4) and cover (3) and secure with

eight washers (2) and eight screws (1).

NOTE

Follow-on Maintenance:

•

Install flywheel (Para 8-9).

•

Install piston and connecting rod assemblies

(Para 3-13).

END OF TASK

3-81

|