| |

TM 10-3930-669-34

3-14. CRANKSHAFT REPLACEMENT/REPAIR (CONT).

The main bearings are of thin-shell type. Their proper installation requires that webs in crankcase

be in alinement and for bearing bores to be preloaded. No attempt should be made to adjust or

recondition bearing shells. Severe engine damage may result.

(6)

Check preloading of bearing bores as follows:

(a)

Position bearing caps, making sure that their identification number match with those stamped in crankcase.

Torque bolt in accordance instructions given in Table 3-1.

(b)

Using a micrometer and precision gauge, set gauge to 2.93 inches (74.5 mm).

(c)

Measure each main bearing bore at points 1 and 2 in plane "a," then in the same manner in plane "b" offset

by 90 degrees.

(d)

If the recorded value is between 2.933 inches (74.50 mm) and 2.9334 inches (74.508 mm), respective

bearing is in acceptable condition and required preload will be obtained when bearing halves are installed.

(e)

If recorded bearing bore diameters differ from the specified values given above, repeat measurements with

new bearing halves installed.

d.

Assembly.

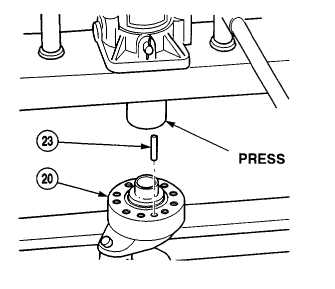

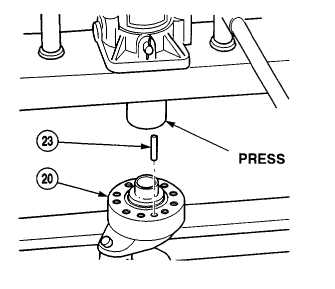

(1)

Using a press, install pin (23) in crankshaft

(20).

3-78

|