| |

TM 10-3930-669-34

c.

Cleaning/lnspection.

WARNING

•

Dry-cleaning solvent (P-D-680) is TOXIC and flammable. Wear protective goggles

and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes; and do not breathe vapors. Keep away from heat or flame. Never smoke

when using solvent; the flashpoint for type I dry-cleaning solvent is 100°F (38°C)

and for type II is 138°F (50°C). Failure to do so may result in injury or death to

personnel.

•

If personnel become dizzy while using cleaning solvent, immediately get fresh air

and medical help. If solvent contacts skin or clothes, flush with cold water. If

solvent contacts eyes, immediately flush eyes with water and get immediate

medical attention.

(1)

Clean parts in dry-cleaning solvent. Dry all parts using a clean shop rag.

NOTE

All measurements are according to Table 3-1.

(2)

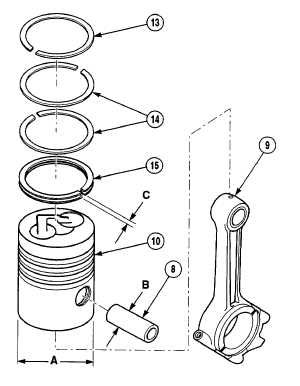

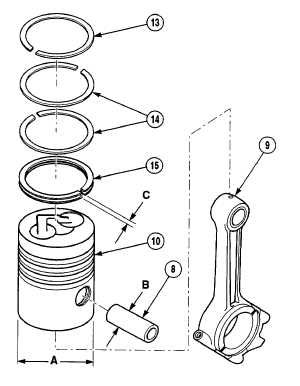

Inspect piston (10) for damage or visible

wear,

including

bosses.

Measure

diameter of piston at position A. Normal

diameter is between 3.9331 in. (99.9010

mm) to 3.9338 in. (99. mm). If not in

range, replace piston.

(3)

Measure outside diameter of pin (8) at

position B. Normal diameter is between

1.3777 in. (34.9940 mm) to 1.3779 in.

(35.0000 mm). If not in range, replace pin.

(4)

Measure ring grooves on piston (Table 3-

1).

(5)

Measure trapezoidal ring (13), taperfaced

rings (14), and oil control ring (15) at

position C (Table 3-1). Insert each piston

ring (one at a time) into cylinder and press

down with piston to a distance of 30 mm

from cylinder head contacting surface.

Measure gap of piston ring and compare

with gap clearance in Table 3-1. If

measurement is wrong, replace ring.

(6)

Make all necessary measurements of

piston

(10)

and

connecting

rod

(9)

assemblies according to Table 3-1.

3-69

|