| |

TM 10-3930-669-34

3-6.

CYLINDER HEAD REPAIR (CONT).

c.

Repair.

CAUTION

Perform all inspections before beginning repairs. Do not reheat cylinder head. Too much heating

may warp head.

NOTE

•

Use the following procedure to make sure cylinder head seating surface is flat and

square.

•

Remove as little material as possible to achieve a perfect sealing surface.

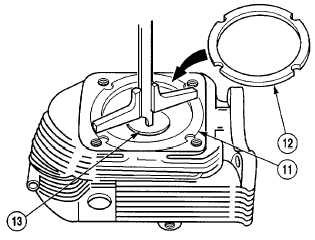

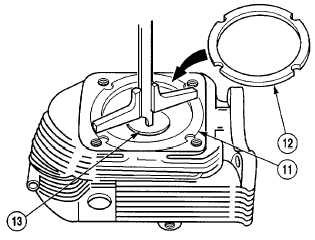

(1) Check cylinder head seating surface (11).

Surface must be flat and square. Minor damage

to seating surface can be removed by grinding

cylinder head on cylinder with abrasive stone.

(2) If cylinder head seating surface (11) is more

severely damaged, replace cylinder head (Para

3-5).

NOTE

•

Use the following procedure to make sure valve springs, valve rotators, spring caps,

valves, and valve seats are within specification.

•

Measurement must be made with intermediate ring inserted.

(3) Inspect intermediate ring (12). Replace if damaged.

(4) After refacing cylinder head seating surface (11), measure clearance between cylinder head bottom and cylinder

head seating surface. If measured value is not between 0.2323 in. (5.9000 mm) and 0.2519 in. (6.4000 mm),

replace valve seats (13).

(5) Inspect valve seats (13). Measure distance between crown of valve and cylinder head seating surface (11). If

measured distance is not between 0.2000 in. (5.0800 mm) and 0.2205 in. (5.6000 mm), replace valve seats.

3-44

|