| |

TM 10-3930-669-20

E-4. TORQUE INSTRUCTIONS.

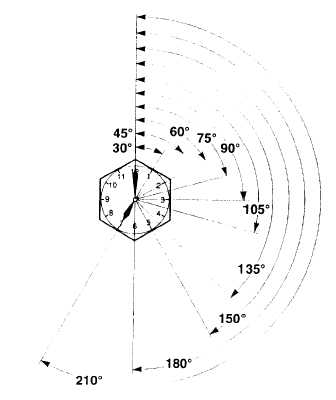

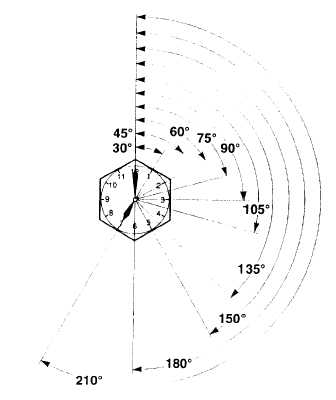

Preloading is applied with a torque wrench that is calibrated in foot pounds (lb-ft) or newton meters (N•m). Preloading is

applied before angle torques. All angle torques listed in Table E-1 are accomplished by turning the screw/nut a specific

number of degrees from a zero reference point as shown. The tightening angle is obtained by turning the handle of the

wrench being used to the desired angle selected from a clock face you mentally superimpose over the screw head.

Torquing of two or more screws securing one assembly should be accomplished in an alternating fashion to ensure

assembly seating and equal load distribution. For example, if angle torque specified is 30° initial then 30° final, proceed

as follows:

a.

Coat screw and surface under screw head

with engine oil, MIL-L-2104.

b.

Set screws squarely to ensure assembly

seating.

c.

Apply specified preload with torque wrench.

d.

Using angle torque meter and socket

wrench, apply 30° initial torque to screw 1.

e.

Apply 30° initial torque to screw 2.

f.

Apply 30° final torque to screw 1.

g.

Apply 30° final torque to screw 2.

Table E-1. Torque Specifications

Preloading

Angle in Degrees or

Total

Torque Values

Application

Ib-ft

N•m

Stage 1

Stage 2

Stage 3

Stage 4

Degree

lb-ft

N•m

Cylinder head

29.5

40

45°

45°

45°

30

165°

-

-

Cylinder head screw

-

-

-

-

-

-

-

59-66

80-90

plug

Rocker arm bracket

-

-

-

-

-

-

-

21

28

nut

Rocker chamber

-

-

-

-

-

-

-

7

10

cover screw

-

(+4; 2)

(+5; 3)

E-2

|