| |

TM 10-3930-664-24

3.

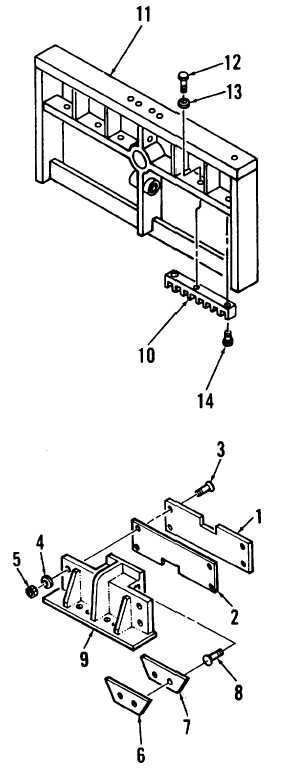

Remove fork positioners (10) from carriage

weldment (11) by removing screws (12, 14) and

washers (13).

B.

CLEANING

Clean carriage assembly components in accordance

with paragraph 1-24.

C.

INSPECTION

1.

Inspect carriage assembly components in

accordance with paragraph 1-24.

2.

Inspect wear pads and shims for uneven or

excessive wear. Replace pads if worn.

D.

REPAIR

Repair of the carriage assembly consists of removal and

replacement of defective, deformed, or damaged

components and worn pads.

E.

ASSEMBLY

1.

Apply loctite to threads of screws (12, 14). Install

fork positioners (10) onto carriage weldment (11)

using screws and washers (13).

2.

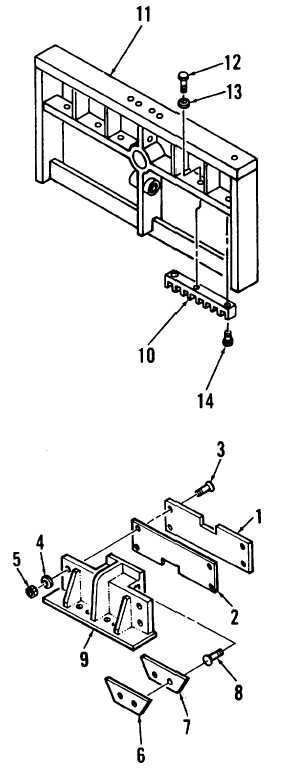

Install wear pad (6) and shim (7) onto upper carriage

retainer (9) by pushing wear pad onto heads of

screws (8).

3.

Install wear pad (1) and shim (2) onto upper carriage

retainer (9) using screws (3), washers (4), and

nuts (5).

FOLLOW-ON MAINTENANCE:

Install carriage assembly (para. 3-65)

END OF TASK

4-107

|