| |

TM 10-3930-664-24

7.

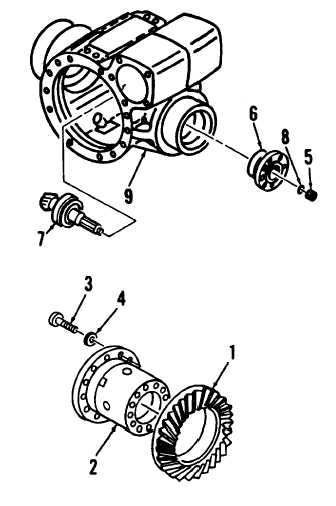

Install new O-ring (8) onto bevel gear shaft (18).

Install nut (5) and torque to 192 to 222 ft-lbs. (260

to 300 N•m).

8.

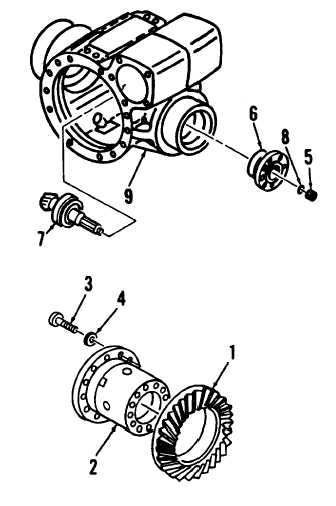

Install large bevel gear (1) onto differential case (2).

9.

Apply loctite to threads of twelve new bolts (3) and

install with washers (4). Torque bolts to 46 to 53 ft-

lbs. (69 to 72 N•m).

10. Install differential gear case (para. 4-32).

11. Measure from center-line of axle to shoulder of

closed end pinion bearing to determine bevel pinion

(7) mounting distance. Compare this measurement

with factory recommended mounting distance

recorded during removal.

12. Remove bevel pinion components and add or

subtract shims (14, 16) until actual mounting

distance matches factory recommended mounting

distance.

FOLLOW-ON MAINTENANCE:

None

END OF TASK

4-92

|