| |

TM 10-3930-664-24

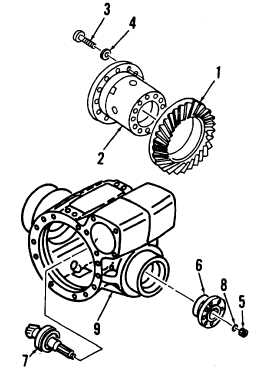

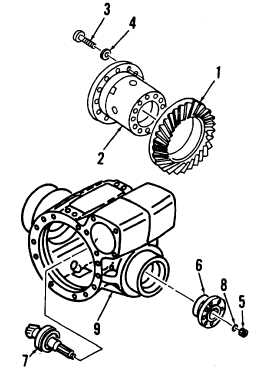

4-33. BEVEL GEAR REPLACEMENT (REAR AXLE ASSEMBLY)

This task covers: Removal, Cleaning, Inspection, and Installation

INITIAL SETUP:

Tools and Test Equipment:

Equipment Condition:

General Mechanics Tool Kit (1, App. E)

Differential gear case removed

Torque Wrench (32, App. E)

(para. 4-32)

Puller Kit (26, App. E)

3/4" Drive Socket Set (55, App. E)

Arbor Press (25, App. E)

Materials / Parts:

Loctite No. 270 (22, App. C)

Bolt, Item 3 (12 ea.)

O-Ring, Item 8 (1 ea.)

Shim, Item 14 (As required)

Shim, Item 16 (As required)

A. REMOVAL

1.

Remove large bevel gear (1) from differential case

(2) by removing twelve bolts (3) and washers (4).

Discard bolts.

2.

Remove nut (5) and pull flange (6) off assembled

bevel pinion (7). Remove and discard O-ring (8).

3.

Using a bearing puller, press assembled bevel

pinion (7) toward inside of differential housing (9).

Remove assembled bevel pinion from axle housing.

4.

Bevel pinion (7) is stamped with a factory

recommended mounting

distance (center-line of

axle to shoulder of closed end bearing). Note and

record this distance for use during installation.

4-90

|