| |

TM 10-3930-664-24

4.

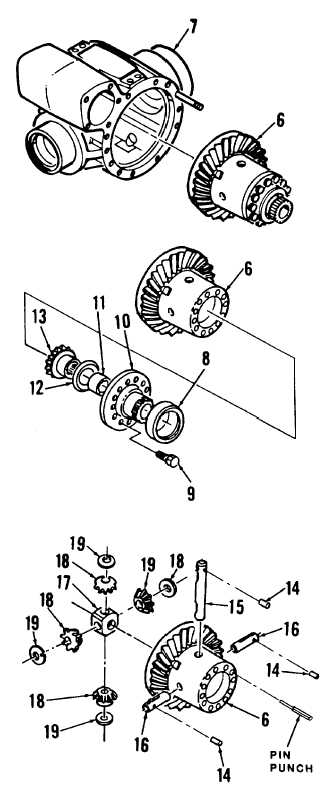

Carefully remove assembled differential gear case

(6) from axle housing (7).

5. Remove bearing cone (8) from gear case (6).

6. Remove twelve bolts (9) from sprocket (10).

Remove sprocket, thrust bearing (11), friction

washer (12), and differential gear (13) from gear

case (6).

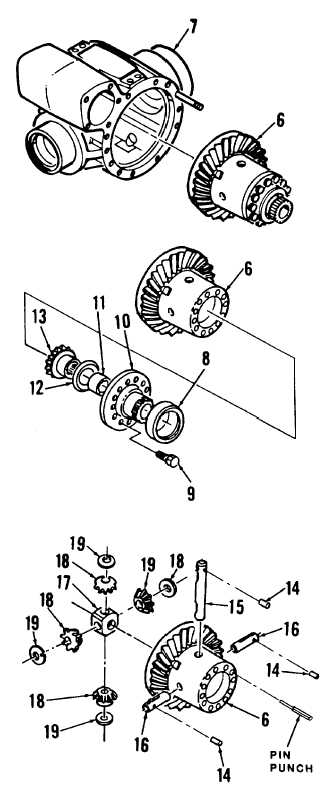

NOTE

Shafts (15, 16) are marked with a part

number on one end. Holes for pins

(14) are located on marked end.

Two different lengths of shaft are

used; one long (15) and two short

(16).

7. Using a soft head hammer and pin punch, drive pins

(14) fully into shafts (15, 16). Depth from face of

gear case (6) to top of pins shall be 41 mm (see

figure).

8. Extract shafts (15, 16) from gear

case

(6).

Remaining parts will fall loose into case.

9. Remove pins (14) from shafts (15, 16).

10. Remove shaft retainer (17), differential pinions (18),

and friction washers (19) from gear case (6).

B. CLEANING

Clean components in accordance with paragraph 1-24.

C. INSPECTION

Inspect components in accordance with paragraph 1-24.

D. INSTALLATION

1. Insert long shaft (15) part way into gear case (6).

Install one friction washer (19) and pinion gear (18)

onto shaft.

2. Push shaft (15) through shaft retainer (17) and install

second pinion gear (18) and friction washer (19).

4-72

|