| |

TM 10-3930-664-24

7.

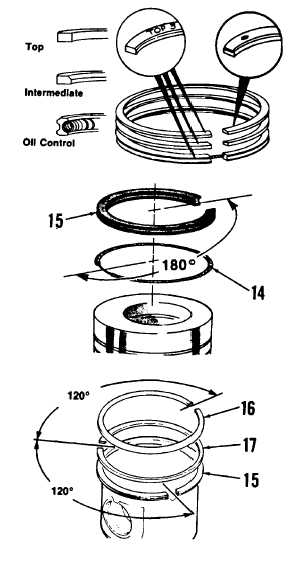

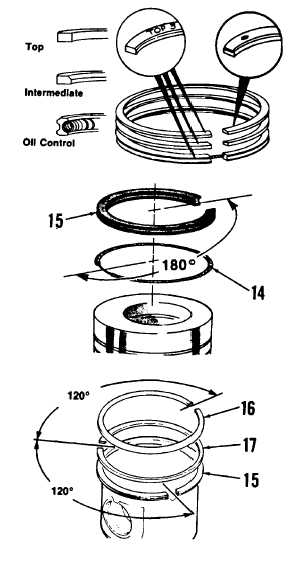

Top surface of each ring in set is identified.

Assemble with the word TOP or supplier mark

up.

8.

Position oil expander ring (14) in oil control ring

groove (bottom groove). Install oil control ring

(15) with end gap opposite ends on expander

ring.

9.

Install top and intermediate rings (16, 17) into

appropriate grooves. Position ring gaps as

shown in figure. Make sure ring gaps do not

align with center of piston pin or along center line

of connecting rod.

10.

Bar crankshaft so that rod journal for piston to be

installed is at bottom dead center (BDC).

11.

Install upper bearing halves into connecting rods.

Lubricate bearing halves with Lubriplate 105.

12.

Lubricate piston skirt, rings, and cylinder bore

with clean lubricating oil.

13.

Compress

rings

(15,

16,

17)

using

ring

compressor.

4-25

|