| |

TM 10-3930-664-24

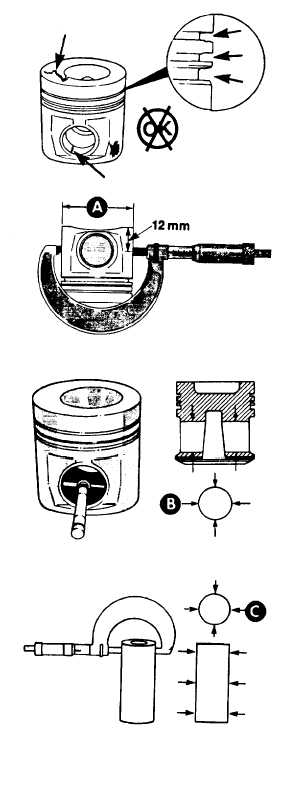

C. INSPECTION

1.

Conduct general inspection of pistons, pins, and

connecting rods in accordance with paragraph 1-

24.

2.

Inspect pistons for damage and excessive wear.

Inspect top, ring grooves, skirt, and pin bore for

chips or cracks.

3.

Measure piston skirt diameter (dimension A).

Minimum diameter shall be 4.0088 in.(101.823

mm).

4.

Use a new piston ring to measure clearance in

ring grooves. Maximum clearance for each ring

groove shall be as follows:

a.

Top groove: 0.006 in (0.150 mm).

b.

Intermediate groove: 0.006 in (0.150 mm).

c.

Oil control groove (bottom): 0.005 in

(0.130 mm).

4.

Measure pin bore in piston (dimension B).

Maximum diameter shall be 1.5758 in. (40.025

mm).

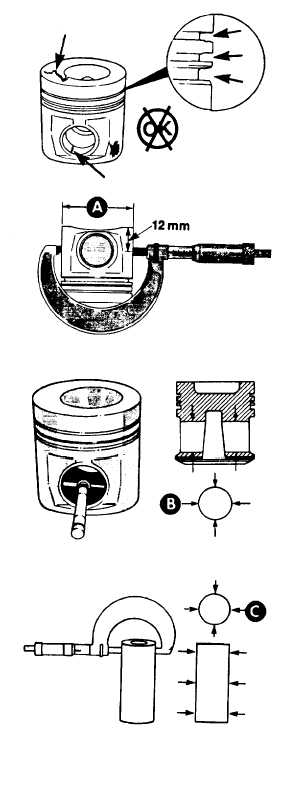

5.

Inspect

piston

pin

for

nicks,

gouges,

or

excessive wear. Measure pin diameter

(dimension C). Minimum diameter shall be

1.5744 in. (39.990 mm).

4-23

|