| |

TM 10-3930-664-24

3.

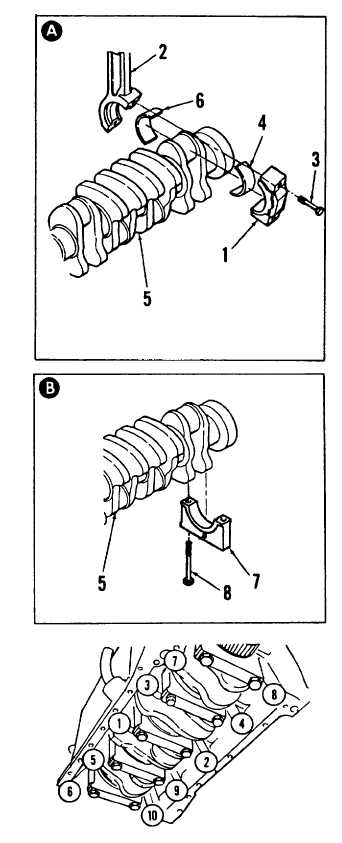

Install upper bearing halves (6) onto

connecting rods (2). Lubricate bearings with

Lubricate 105.

4.

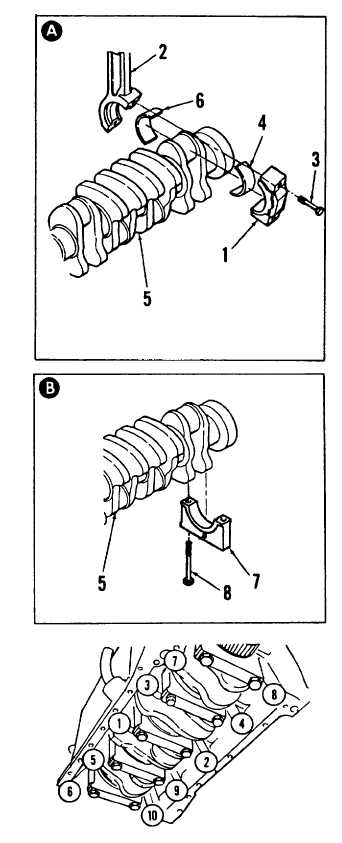

Ensure main bearings are installed in block and

main bearing caps. Carefully install crankshaft

(5) into cylinder block.

5.

Lightly lubricate screws (8) with lubricating oil.

Install main bearing caps (7) onto cylinder block

using screws. Torque screws in sequence

shown in three steps:

a.

Step 1: 44 ft-lbs (60 Nm).

b.

Step 2: 88 ft-lbs (119 Nm).

c.

Step 3: 129 ft-lbs (176 Nm).

6.

Manually rotate crankshaft (5) to ensure smooth

operation. If crankshaft does not rotate freely,

remove crankshaft and inspect main bearings.

7.

Install lower bearing halves (4) into lower halves

of connecting rods (1). Lubricate bearings with

Lubricate 105.

8.

Lightly lubricate screws (3) with lubricating oil.

Install lower halves of connecting rods (1) onto

upper halves (2) using screws. Tighten screws

in three steps:

a.

Step 1: 26 ft-lbs (35 Nm).

b.

Step 2: 52 ft-lbs (71 Nm).

c.

Step 3: 74 ft-lbs (100 Nm).

FOLLOW-ON MAINTENANCE:

Install oil suction connection

(para. 3-15)

Install flywheel housing (para. 3-10)

Install engine gear cover (para. 3-12)

Install gear housing (para. 4-16)

END OF TASK

4-17

|