| |

TM 10-3930-664-24

7.

Inspect valve stem tip for flatness. If required,

resurface valve stem tip.

8.

Grind valve seat as follows:

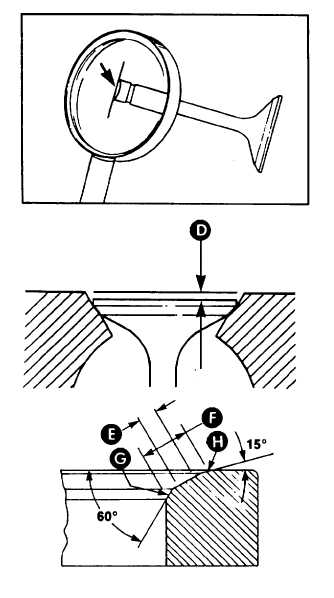

a.

Install valve in designated bore and

measure

valve

depth

(dimension

D).

Valve depth is the distance from valve

face to head deck. Record depth and

remove valve from bore.

b.

Grind valve seat to remove scores,

scratches, and burns. Ensure seat

angles are maintained. Intake angle must

be 30 degrees. Exhaust angle must be 45

degrees.

c.

Reinstall valve and measure valve depth

again. Record depth as D1.

d.

Calculate grind depth (GD) by

subtracting dimension D from dimension

D1. Grind valve seat until GD equals

0.010 in (0.254 mm).

D1 D = 0.010 inch (GD)

e.

Reinstall valve seat and measure valve

depth again. Depth shall be 0.0389 to

0.0598 in (0.99 to 1.52 mm). Replace

valve if out of limits.

f.

Repeat steps a through e for remaining

valves.

9.

Apply a light coat of lapping compound to each

valve. Lap valves to companion seats.

10.

Remove valves. Clean lapping compound from

valves and seats.

11.

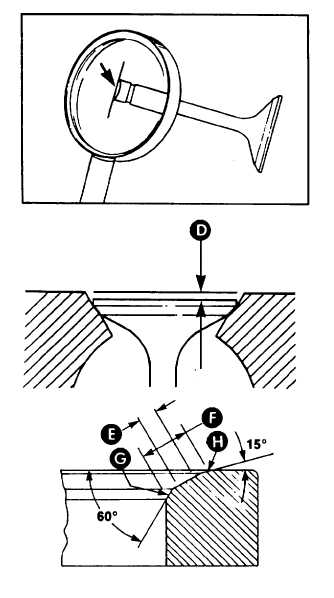

Measure valve seat width indicated by lapped

surface (dimensions E AND F). Width E shall

not exceed 0.060 in. (1.5 mm). Width F shall

nor exceed 0.080 in. (2.0 mm).

12.

Grind areas G and H, as required, to center seat

on valve face. Grind area G with a 60 degree

stone and area H with a 15 degree stone.

4-12

|