| |

TM 10-3930-664-24

E. REPAIR

1.

Repair of the lift cylinders consists of removal

and replacement of defective, deformed, or

damaged components.

2.

Replace all rings, wipers, and seals with new

components from seal kits.

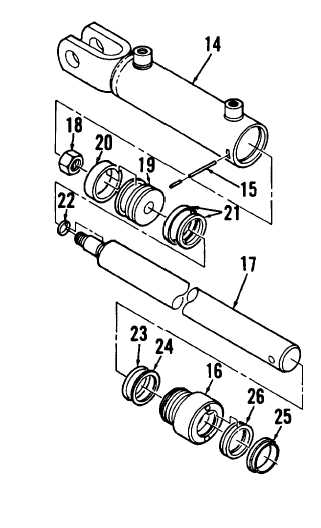

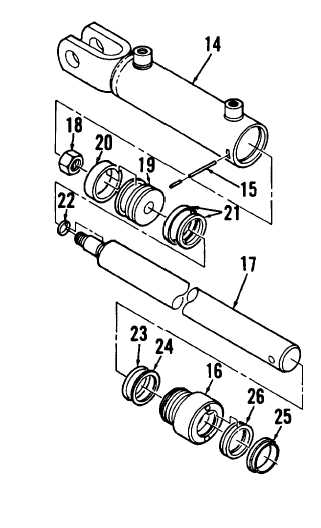

F. ASSEMBLY OF MAIN LIFT CYLINDER

1.

Lubricate new O-ring (22) with clean lubricating

oil and install onto rod assembly (17).

2.

Install new seal (26), wiper (25), and backup ring

(24) onto gland (16). Lubricate new O-ring (23)

with clean lubricating oil and install.

3.

Install new piston seal (21) and wear ring (20)

onto piston (19).

4.

Lubricate I.D. of gland (16) and piston (18) with

grease and install onto rod assembly (17).

5.

Install clevis end of rod assembly (17) in a vise.

Install piston nut (18) and torque to 75 to 100 ft-

lbs (100 to 135 Nm).

CAUTION

Use

care

when

installing

piston

assembly (17) to prevent damage to

seals, rings, and inside of cylinder

barrel (14). Lock ring groove in barrel

may contain small burrs. Deburr

using emery cloth.

6.

Lubricate O.D. of piston (19) and gland (16) with

grease. Carefully install barrel (14) over rod

assembly (17).

7.

Tap gland (16) into barrel (14) until it seats.

Insert lockwire (15) through barrel slot and into

hole in gland.

8.

Using spanner wrench, rotate gland (16) to the

right until lockwire is completely installed.

3-226

|