| |

TM 10-3930-664-24

3.

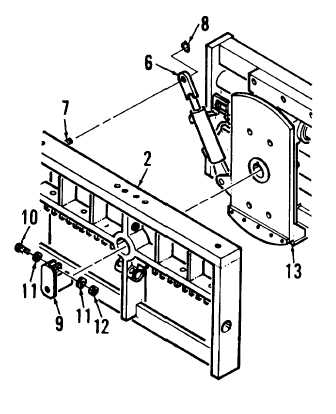

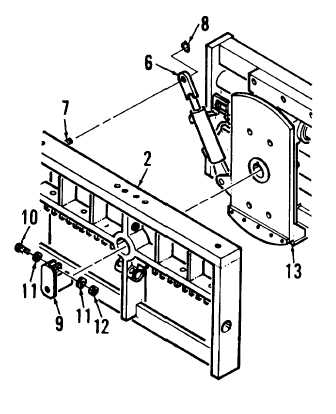

Release rotate cylinder (6) from stub shaft (7) on

rotate carriage by removing retainer (8).

WARNING

Carriage assembly

is

heavy

and

awkward. Enlist the help of an aide

when removing to prevent injury to

personnel

and

damage

to

components.

4.

Attach lifting sling to carriage weldment (2).

Attach hoist to secure carriage weldment

during removal.

5.

Release rotate carriage pin (9) from carriage

weldment (2) by removing screw (10), washers

(11), and nut (12). Discard nut (12).

6.

Remove rotate carriage pin (9) from carriage

weldment (2). Separate carriage weldment from

sideshift carrier (13).

B. CLEANING

Clean carriage assembly in accordance with paragraph

1-24.

C. INSPECTION

Inspect carriage assembly and related components in

accordance with paragraph 1-24.

D. INSTALLATION

WARNING

Carriage assembly

is

heavy

and

awkward. Enlist the help of an aide

when installing to prevent injury to

personnel

and

damage

to

components.

1.

Using hoist, mate carriage weldment (2) to

sideshift carrier (13). Install rotate carriage pin

(9) using a soft head hammer.

2.

Secure rotate carriage pin (9) to carriage

weldment (2) using screw (10), washers (11),

and new nut (12).

3.

Secure rotate cylinder (6) to stub shaft (7) using

retainer (8).

3-215

|