| |

TM 10-3930-664-24

15.

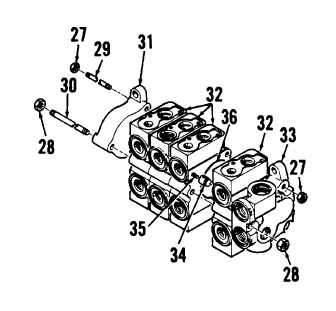

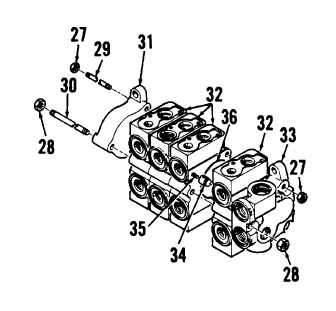

Remove nuts (27, 28) from tie rods (29, 30).

Remove tie rods and separate outlet housing

(31), spool housings (32), and inlet housing (33).

16.

Remove four poppets (34) and springs (35) from

spool housings (32). Remove and discard O-

rings (36).

B. CLEANING

Clean

directional

control

valve

components

in

accordance with paragraph 1-24.

C. INSPECTION

1.

Conduct overall inspection of directional control

valve components in accordance with paragraph

1-24.

2.

Inspect spools and spool bores for damage or

deformation. Check for evidence of excessive

or uneven wear.

3.

Inspect outlet, inlet, and spool housings for

cracks. Inspect mating surfaces for damage that

may prevent a proper seal. Check for evidence

of leakage.

D. REPAIR

Repair of the directional control valve assembly consists

of removal and replacement of defective, deformed, or

damaged components.

E. ASSEMBLY

1.

Lubricate new O-rings (36) with clean lubricating

oil and install into inlet housing (33) and spool

housings (32).

2.

Insert four poppets (34) and springs (35) into

spool

housings

(32)

as

each

section

is

assembled.

3.

Mate outlet housing (31), spool housings (32),

and inlet housing (33). Inset tie rods (29, 30)

and install nuts (27, 28). 3. Torque nuts (27) to

13 to 15 ft-lbs (18 to 20 Nm). Torque nut (28) to

30 to 36 ft-lbs (41 to 49 Nm).

3-208

|