| |

TM 10-3930-664-24

B. CLEANING

1.

Clean

hydraulic

pump

components

in

accordance with paragraph 1-24.

2.

Clean seal grooves well to ensure all foreign

material is removed. Dirt or other contaminants

will prevent proper seal installation, causing

leakage.

C. INSPECTION

1.

Inspect pump components in accordance with

paragraph 1-24.

2.

Inspect bearing blocks for damage. Bearings

shall rotate freely in races.

3.

Inspect gear journals and faces for damage.

Inspect for damage gear teeth. Replace if faces

or journals are scored.

D. RFPAIR

Repair of the hydraulic pump consists of removal and

replacement of defective, deformed, or damaged

components.

E. ASSEMBLY

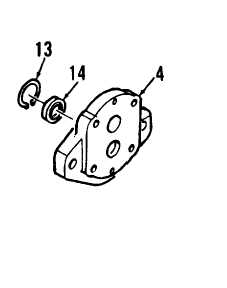

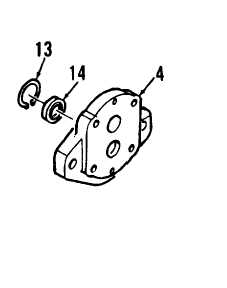

CAUTION

Use care when installing oil seal (14)

to

prevent

damage

to

mounting

flange (4). Seal must be seated

evenly.

1.

Place mounting flange (4) on a clean work

surface, oil seal bore facing up.

2.

Place new oil seal (14) into mounting flange

bore, part number side up. Apply even pressure

to oil seal to seat into bore. Install retaining ring

(13).

3-203

|