| |

TM 10-3930-664-24

D. REPAIR

Repair of the steering valve consists of removal and

replacement

of

defective,

deformed,

or

damaged

components.

E. ASSEMBLY

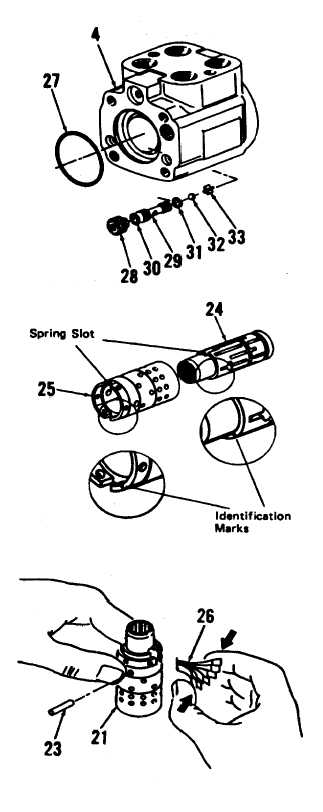

1.

Use tweezers or needle nose pliers to lower

retainer (33) into housing (4). Ensure retainer

is straight (not tilted). Install check ball (32).

2.

Install new seals (30, 31) onto check ball seat

(29). Lubricate seat and seals. Install seat into

housing (4), open end of seat first.

3.

Install set screw (28) into housing (4). Use 1/4

inch hex key to torque set screw to 100 in-lbs

(11 Nm).

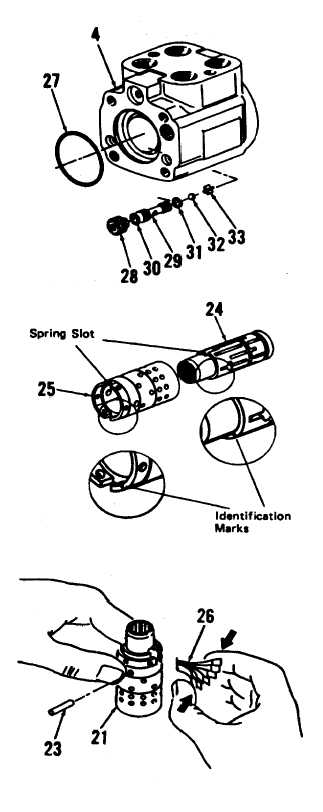

4.

Assemble spool (24) and sleeve (25), ensuring

spring slots are properly aligned. Some spool

and sleeve sets have identification marks.

Align these marks.

5.

Test spool and sleeve assembly (21) for free

rotation. Spool (24) should rotate smoothly in

sleeve (25) with fingertip force applied at splined

end.

6.

Align spring slots and stand parts on bench.

7.

Assemble all six centering springs (26) on bench

so that extended edges are down and arched

center sections are together.

8.

Insert two outer springs (26) into spring slots of

spool

and

sleeve

assembly

(21).

Insert

remaining springs one at a time between the two

outer springs until all springs are in the spool and

sleeve assembly.

9.

Center spring set in spring slot. Seat springs

evenly, flush with upper surface of spool and

sleeve assembly (21).

10.

Push pin (23) into spool and sleeve assembly

(21) until pin is flush on both sides.

3-152

|