| |

TM 10-3930-664-24

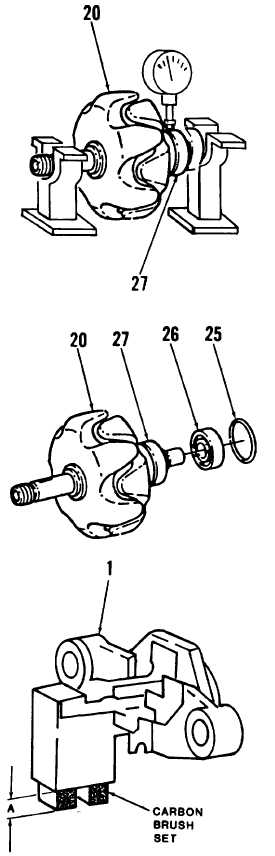

14. Mount rotor (20) in test stand as shown in figure.

Using dial indicator, conduct true-running test at the

following points:

- OD of rotor (20)

- OD of collector rings (27)

Maximum error for rotor (20) is 0.05 mm.

Maximum error for collector rings (27) is

0.03 mm.

15. Remove rotor (20) from test stand.

16. Remove and discard O-ring (25). Using bearing

puller, remove bearing (26) from rotor (20).

17. Unsolder leads of excitation winding from collector

rings (27). Using bearing puller, remove collector

rings from rotor (20).

C.

CLEANING

Clean alternator components in accordance with para-

graph 1-24.

D.

INSPECTION

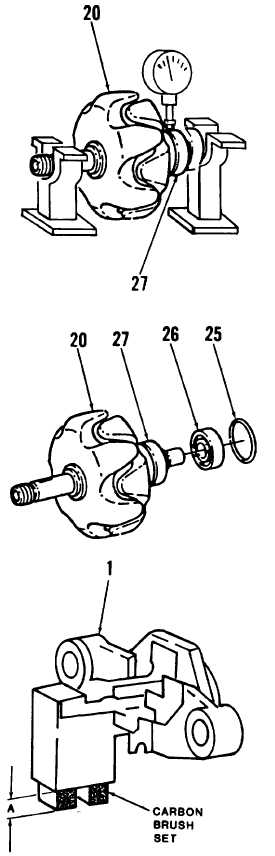

1.

Inspect alternator components in accordance with

paragraph 1-24.

2.

Inspect carbon brushes on transistor regulator (1) for

obvious damage. Brushes shall project 0.27 inches

(minimum).

E.

RFPAIR

CAUTION

Do not allow solder to contact brushes.

1.

If brush set is damaged or brushes project less than

0.27 inches, unsolder brush set and replace. New

brushes shall project 0.39 inches. Check brushes

for freedom of movement after installation.

2.

Repair of the alternator consists of removal and

replacement of defective, deformed, or damaged

components.

3-92

|