| |

TM 10-3930-664-24

2.

Measure clearance between geroter planetary

and

body

bore

(dimension

A).

Maximum

clearance shall be 0.015 in. (0.0381 mm).

3.

Measure

planetary

drive

tip

clearance

(dimension B). Maximum clearance shall be

0.007 in. (0.1778 mm).

4.

Measure clearance between geroter planetary

(4), pump housing (5), and geroter drive (6).

Maximum clearance shall be 0.005 in. (0.127

mm).

5.

Measure

gear

backlash

(dimension

C).

Backlash shall be 0.003 TO 0.013 in. (0.05 TO

0.33 mm).

6.

Replace engine oil pump if the fit and clearance

limits in steps 2 through 5 are not met.

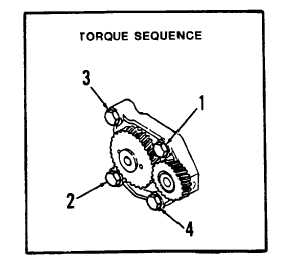

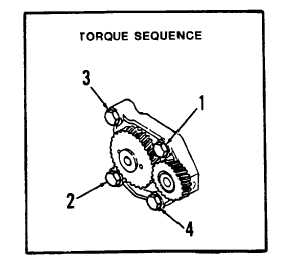

7.

Install back plate (3) onto oil pump (1). Fill oil

pump with clean engine oil.

8.

Mate oil pump (1) to cylinder block, ensuring that

idler gear pin is installed into locating bore in

cylinder block.

9.

Secure oil pump (1) to cylinder block using

screws (2). Torque screws to 18 ft-lbs (24 Nm)

following the sequence shown in figure.

NOTE

Pump back plate (3) seats against

bottom of bore in cylinder block. When

pump is correctly installed. the flange

on pump will not touch cylinder block.

3-59

|