| |

TM 10-3930-664-24

3.

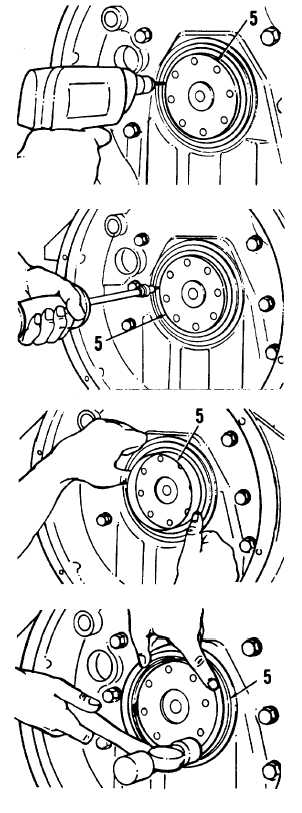

Using an electric drill and 1/8 inch drill bit, drill

two holes (180 degress apart) into outer edge of

oil seal (5).

4.

Install #10 sheet metal screws into drilled holes.

5.

Extract oil seal (5) from carrier using slide

hammer. Discard oil seal.

B.

CLEANING

1.

Clean flywheel in accordance with paragraph 1-

24.

2.

Clean and dry sealing surface of crankshaft.

Seal lip and sealing surface must be free of all

oil residue to prevent leaks.

C.

INSPECTION

1.

Inspect

components

in

accordance

with

paragraph 1-24.

2.

Inspect flywheel ring gear for chipped, missing,

or damaged teeth.

D.

INSTALLATION

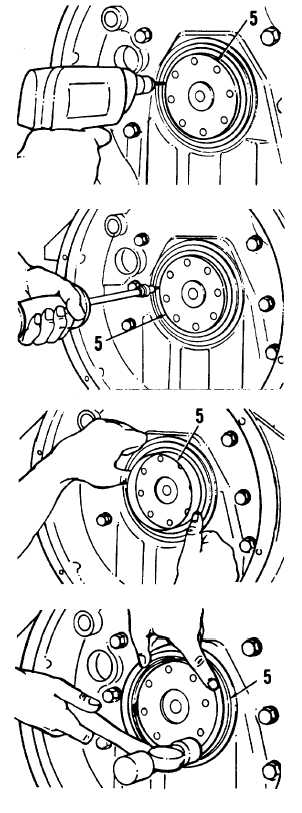

1.

Install

oil

seal

(5)

and

pilot

from

seal

replacement kit onto crankshaft. Push seal into

bore of housing and remove pilot.

NOTE

Use installation tool supplied with

seal replacement kit to install seal to

correct depth.

2.

Install seal (5) by tapping with soft head

hammer. To ensure proper seat, alternate

tapping at 12, 3, 6, and 9 o’clock positions.

3-37

|