| |

TM 10-3930-664-24

15.

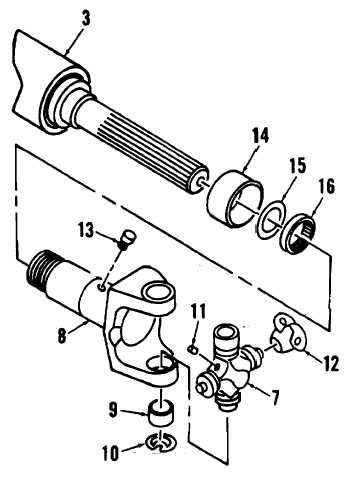

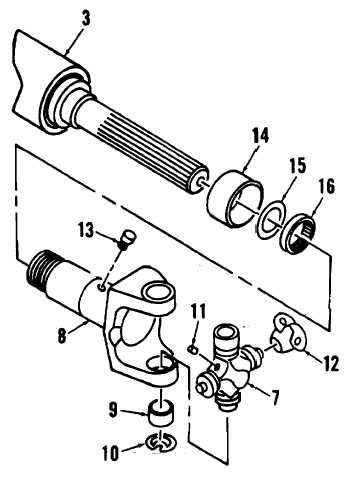

Remove grease fitting (13) from slip yoke (8)

only if replacement is required.

NOTE

Mark shaft assembly (3) and slip yoke

(8) before separating to assist in

alignment during installation.

16.

Remove slip yoke (8) from shaft assembly (3) by

removing dust cap (14), steel washer (15), and

rubber washer (16).

B. CLEANING

Clean drive shafts in accordance with paragraph 1-24.

C. INSPECTION

1.

Inspect drive shaft components in

accordance with paragraph 1-24.

2.

Inspect shafts for damaged, dented, or bent

tubing.

3.

Ensure shaft is free of foreign material, such as

undercoat or concrete. If found, foreign material

shall be removed carefully to avoid damaging

shaft.

4.

Inspect mounting flanges for burrs, paint, or

foreign material.

D. ASSEMBLY

1.

Align slip yoke (8) and shaft assembly (3) using

match-marks. Secure slip yoke onto shaft

assembly using dust cap (14), steel washer (15),

and rubber washer (16).

2.

Install grease fitting (13) into slip yoke (8).

3.

Install bearing trunions (12) onto cross assembly

(7). Secure by driving lockwire into slots in

bearing trunions.

2-280

|