| |

TM 10-3930-664-24

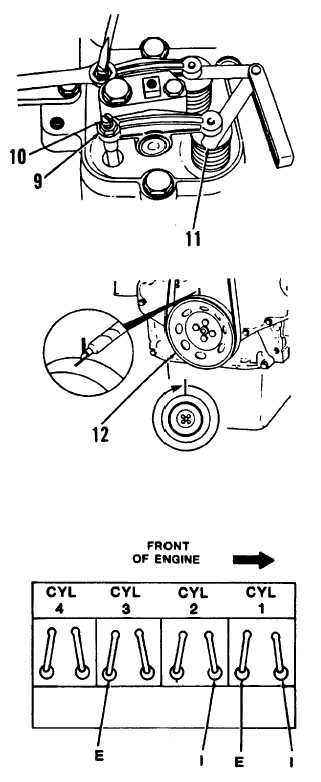

3. ADJUST VALVE CLEARANCE.

a.

Loosen adjusting screw lock nut (9).

b.

Rotate

adjusting

screw

(10)

until

proper

clearance is achieved between rocker lever and

valve stem (11).

c.

Tighten locknut (9). Recheck clearance and

adjust as required.

4. TORQUE LOCKNUT (9) TO 18 FT-LBS (24 Nm).

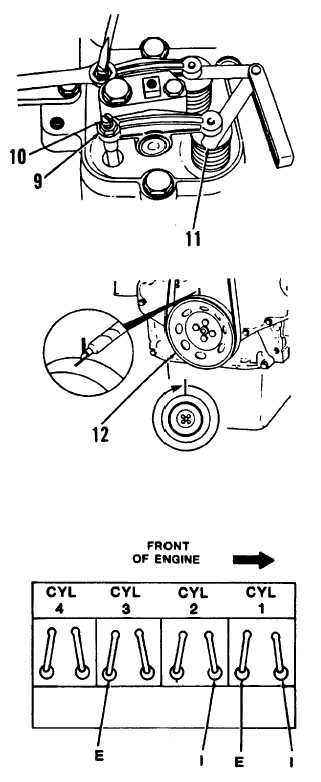

CAUTION

Ensure timing pin is disengaged

before rotating crankshaft.

5.

MATCH MARK CRANKSHAFT PULLEY (12) TO

GEAR

COVER.

MANUALLY

ROTATE

CRANKSHAFT 360 DEGREES.

6

USING A FEELER GAGE, CHECK REMAINING

VALVES FOR PROPER CLEARANCE.

a.

Intake valve (I) clearance shall be 0.010 in

(0.254 mm).

b.

Exhaust valve (E) clearance shall be 0.020 in

(0.508 mm).

7.

ADJUST

VALVE

CLEARANCE

(STEP

3)

IF

REQUIRED.

2-72

|