| |

TM 10-3930-664-10

SECTION III. Maintenance Procedures

3-4. INTRODUCTION

This section contains maintenance procedures which are the responsibility of the operator. See paragraph 2-5, Preventive

Maintenance Checks and Services for additional maintenance not covered in this section. The maintenance procedures in

this manual are authorized by the Maintenance Allocation Chart (refer to TM10-3930-664-24).

3-5. ENGINE OIL SAMPLING VALVE - SERVICE

This task covers:

Obtaining an engine oil sample for the Army Oil Analysis Program (AOAP).

1.

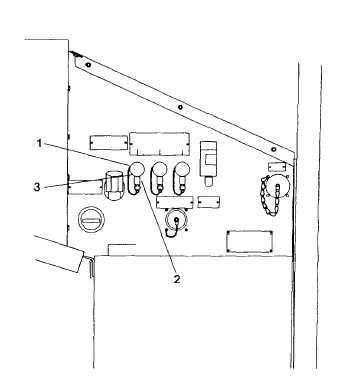

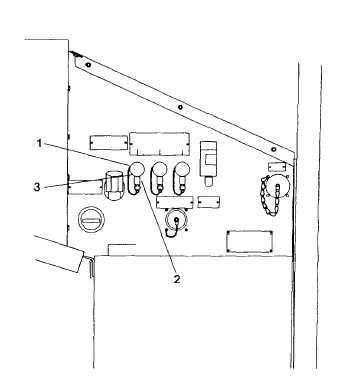

CLEAN THE ENGINE OIL SAMPLING VALVE (1).

2.

START THE ENGINE, PARAGRAPH 2-9. BRING

IT TO NORMAL OPERATING TEMPERATURE.

3.

OBTAIN THE OIL SAMPLE.

a.

With the engine at idle, remove the dust cap

(2) on the engine oil sampling valve (1).

b.

Place a clean container under the valve (1)

spout.

c.

Rotate the knob (3) clockwise to drain

approximately one pint (.47 liters) of oil prior to taking a

sample. Release the knob (3) to close the valve.

d.

Place a sample bottle under the valve (1)

spout and fill to it within 1/2 inch (1.27 cm) from top.

Release the knob (3) to close the valve. Cap the bottle

immediately.

e.

Install the dust cap (2) on the oil sampling

valve(I). Tighten dustcap only finger tight. Return the

oil drained into container during step c to the engine.

f.

Check oil level and add oil if necessary.

Refer to LO10-3930-664-12.

3-14

|