| |

TM 10-3930-660-34

3-7.

CYLINDER HEAD ASSEMBLY - REPLACE/REPAIR (Cont’d)

NOTE

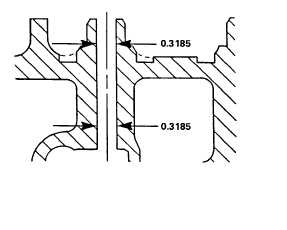

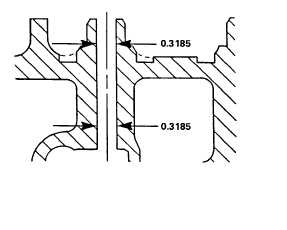

The cylinder head has integral valve guides. Service valve guides can be installed to meet tolerance specifications after

cylinder head is machined.

4.

INSPECT VALVE GUIDE BORES.

Inspect valve guide bores for scuffing or scoring. If guide bores are scuffed or scored, service valve guides must be

installed. See REPAIR heading.

5.

MEASURE VALVE GUIDE BORE. MAXIMUM ALLOWABLE

DIAMETER IS 0.3185 INCH.

If guide bores are worn, service valve guides must be installed. See

REPAIR heading.

6.

INSPECT VALVE SEATS.

a.

Inspect valve seats for scoring, scratches, or a burned

condition.

b.

If a valve seat is scored, scratched, or burned it must

be ground or replaced. See REPAIR heading.

7.

INSPECT VALVE SPRINGS.

Visually inspect valve springs for nicks, deep scratches, rust deposits, notches at the end of the spring, and for wear

between coils.

3-40

|