| |

TM10-3930-660-34

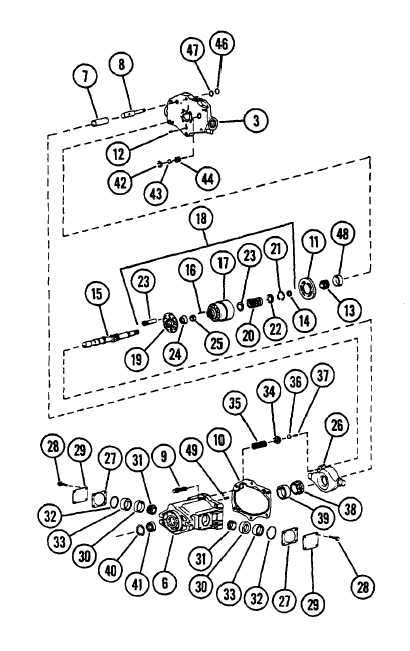

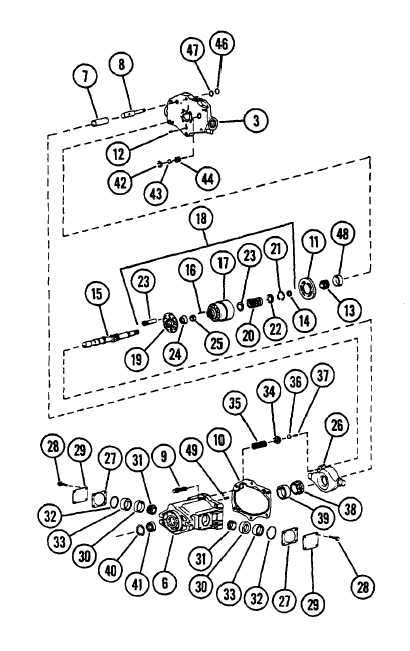

16-21.PISTON PUEP - REPAIR (Cont’d)

f. Install pin retainer (24) into

cylinder block (17) with the open

end of retainer facing away from

the large spline openings.

Position pin retainer (24) so

that it is approximately 1/4 inch

below the surface of the cylinder

block.

g. Install three pins (16) into

cylinder block (17) until they

bottom against spring washer (23)

already installed in cylinder

block.

h. Place spherical washer (24) on

top of the three pins (16).

Install shoe plate (19) and nine

piston and shoe assemblies (23)

over spherical washer (24) and

into cylinder block (17).Move

shoe plate (19) in a side to side

and up and down motion to make

sure each piston moves freely in

its bore.

i. Place housing (6) on its side and

hold shaft (15) horizontal.

Install rotating group parts (18)

into housing (6).Turn shaft (15)

to match splines in cylinder

block (17) and spherical washer

(24).

j. Place new gasket (10) over pins

(49) and put housing (6) aside

for final assembly.

9. ASSEMBLE AND INSTALL VALVE BLOCK

(3).

NOTE

Lubricate all moving parts of piston

pump with hydraulic oil to facilitate

assembly and provide initial

lubrication. Pour hydraulic oil

liberally over rotating group parts and

wafer plate as these components are

without lubrication until the pump

primes.

16-141

|