| |

16-21.PISTON PUMP - REPAIR (Cont’d)

b. Measure face thickness of each

shoe. The face thickness of all

shoes must be within 0.001 inches

of each other.

7. INSPECT CYLINDER BLOCK (17).

a. Inspect cylinder block bore for

wear, scratches, and/or erosion

between cylinders. Check the

spring, washers, and retaining

ring located within the cylinder

block for wear.

b. Check each cylinder block bore

for excessive wear by sliding the

piston and shoe subassemblies

through the bores. If binding is

evident, clean cylinder block and

piston, lubricate parts with

clean hydraulic fluid and again

check for binding.

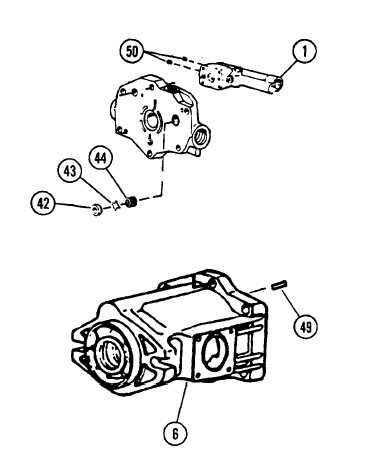

8. INSPECT CHECK VALVE (43).

a. Press check valve (43) against

spring (44).Valve (43) should

return and hold firm against seat

(42).

b. If replacement is necessary,

spring (44), valve (43), and seat

(42) must be replaced as a set.

ASSEMBLY

1. IF REMOVED, INSTALL TWO PLUGS (50) TO

COMPENSATOR (1).

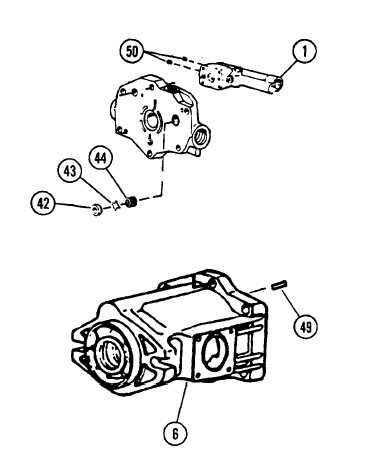

2. IF REMOVED, INSTALL ALIGNMENT PINS

(49) INTO HOUSING (6).

3. INSTALL NEW DRIVE SHAFT BEARING (38)

AND SEAL (41).

a. Use fabricated tool (App. C, Fig.

C-12) and an arbor press to press

shaft (15) through bearing (38).

Press shaft until bearing (38)

bottoms against drive shaft (15)

shoulder.

16-134

|