| |

TM10-3930-660-34

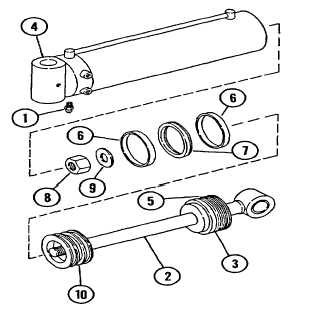

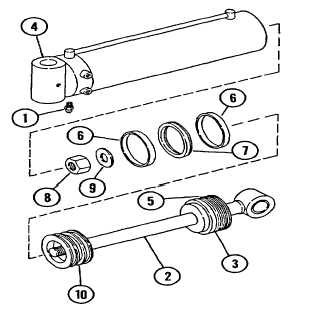

16-10. CARRIAGE TILT CYLINDER - REPAIR (Cont’d)

3.

DISASSEMBLE CYLINDER PARTS (2-16).

CAUTION

Do not scratch or damage the wear

surface of rod (2), piston (10) or gland

(3).Follow this precaution to prevent

failure of the cylinder.

a.

Use a suitable

tool

to

pull

rod

(2)

out

approximately 5 inches for removal of gland (3).

b.

Place a container under gland (3) to catch oil

contained in cylinder.

c.

Use a spanner wrench to unscrew gland (3) from

cylinder tube (4). Pull gland (3) out of cylinder

far enough to unseat O-ring (5). Allow oil to

drain into container.

CAUTION

Use care when removing rod (2) and

piston assembly to prevent wear ring (6)

damage. Keep rod (2) in line with

cylinder tube to prevent binding.

d.

Remove rod (2) and piston assembly from

cylinder tube (4).

e.

Place rod (2) and piston assembly on suitable

supports to prevent damage.

f.

Remove two wear rings (6).

CAUTION

Do not nick or scratch seal groove

during removal of seal (7).Failure to

follow this precaution will cause part

damage.

g.

Cut seal (7) and discard.

16-42

|