| |

TM10-3930-660-34

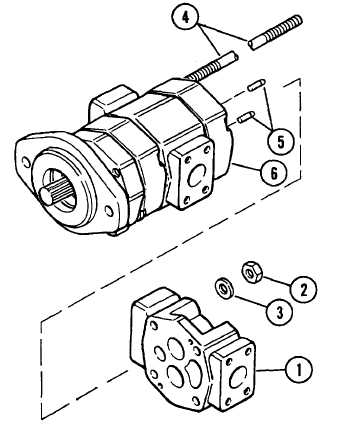

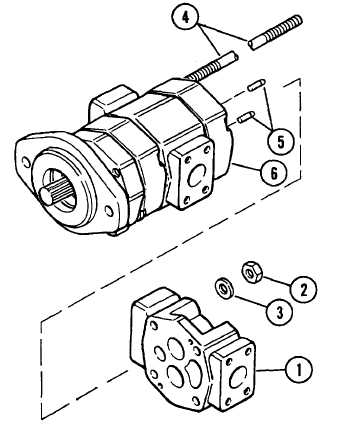

16-3. TANDEM GEAR PUMP - REPAIR

This task covers:

a.

Removal

c.

Inspection

e.

Pre-Load Check of Bearing

b.

Disassembly

d.

Reassembly

f.

Installation

INITIAL SETUP:

Tools

Shop Equipment, Automotive

Maintenance and Repair, Common

#1 Less Power

Fabricated Tools for Repair:

Fabricated Tool - Seal Removal Tool

(App. C, Fig. C-l)

Fabricated Tool - Drive Gear

Installation Tool (App. C, Fig. C-2)

Equipment Condition

Tandem gear pump removed,

TM10-3930-660-20.

Materials/Parts

Grease (App. B, Item 11)

Hydraulic Oil (App. B, Item 35)

Lint-Free Rag (App. B, Item 38)

Loctite 9242 (App. B, Item 41)

Permatex Form-A-Gasket No. 3 Sealant

(App. B, Item 47)

Seals (9, 13, 16, 22, 27, 29, 31)

DISASSEMBLY

CAUTION

Prying notches are provided between the pump

sections.

If

prying

off

sections

becomes

necessary, take extreme care not to mar or

damage machined surfaces. Excessive force while

prying can result in misalignment and damaged

parts.

1.

PLACE PUMP IN A VISE WITH DRIVE SHAFT

POINTING DOWN. MARK ALL SECTIONS TO BE

USED FOR ALIGNMENT AT ASSEMBLY.

2.

REMOVE THE COVER (1).

a.

Remove four nuts (2) and washers (3) from studs

(4).

16-10

|