| |

TM10-3930-660-34

9-5 REAR DIFFERENTIAL CARRIER ASSEMBLY - REPLACE/REPAIR/ADJUST (Cont’d)

c. Install eight capscrews (33)

finger tight

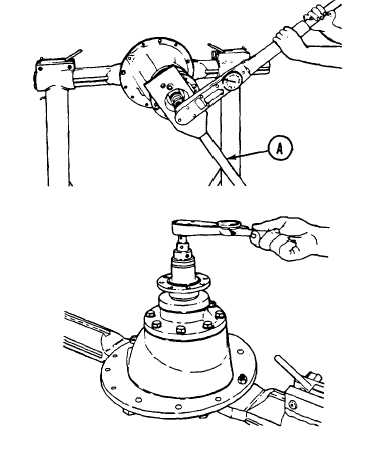

d. Fasten a fabricated yoke nut tool

(App B, Fig, C-5) to companion yoke

(9) Use a fabricated yoke nut tool

(A) to hold bevel pinion (29) in

position when nut (31) is tightened

e. Torque nut (31) on bevel pinion

(29) to 300 - 400 lb ft

f.

remove bar from companion yoke

(9)

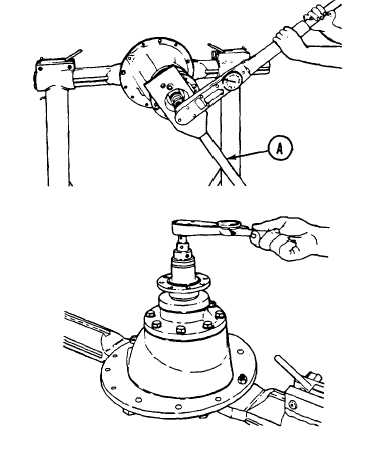

NOTE

Do not read starting torque Read only

torque value after bevel pinion (29)

starts to rotate Starting torque will

give a false reading

g. Attach a lb in torque wrench on

bevel pinion nut (31) Rotate

bevel pinion (29) and read value

indicated on torque wrench New

pinion bearings should be

preloaded between 5 and 45 lb

in of torque Reused pinion

bearings should be preloaded

between 10 and 30 lb in

1). Increase bearing preload by

removing bevel pinion (29)

from bearing cage (30) and

installing a thinner bearing

spacer (40) Repeat STEPS a

through g.

2). Decrease bearing preload by

removing bevel pinion (29)

from bearing cage (30) and

installing a thicker bearing

spacer (40) Repeat STEPS a

through g.

9-16

|