| |

TM 10-3930-660-34

9-5 . REAR DIFFERENTIAL CARRIER ASSEMBLY - REPLACE/RIEPAIR/ADJUST (Cont’d)

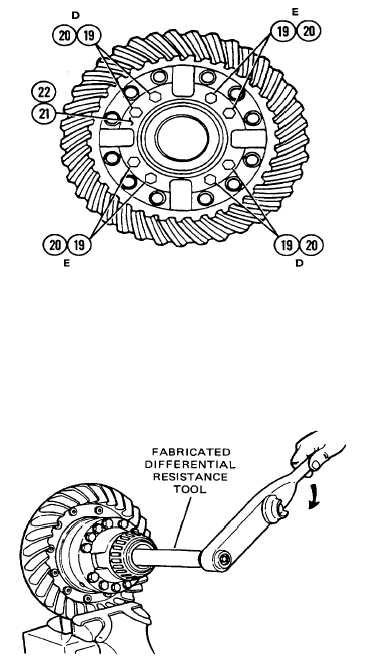

CAUTION

Spacing between first four installed

capscrews (19) must be even to prevent

uneven pressure on case halves when

torquing . Failure to do so could cause

component failure.

q.

Apply Loctite #277 to eight

capscrews (19) . Install four of

the eight capscrews (19) and four

flatwashers (20) , as opposing

pairs (D and E) , into case halves

(21 and 22).

r.

Torque four capscrews (19) to

60-75 lb . ft.

NOTE

Torque capscrews (19) in pairs

opposite each other.

s.

Install remaining four capscrews

(19) and four flatwashers (20).

Torque to 60-75 lb . ft.

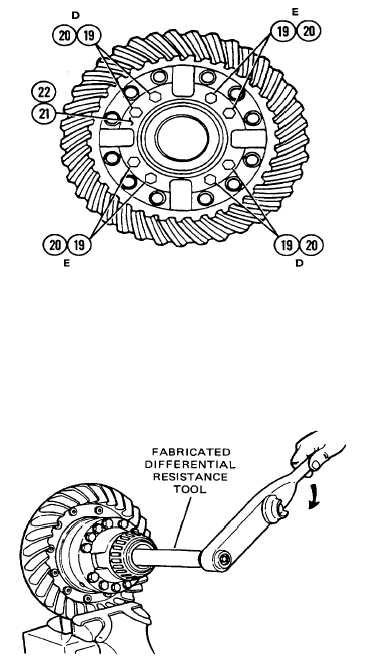

7.

CHECK ROTATING RESISTANCE OF

DIFFERENTIAL GEARS.

NOTE

Fabricate a tool from an axle’s shaft

that matches the spline of differential

side gear (24).

a.

Put differential in a soft-jaw

vise in the normal operating

position.

b.

Install fabricated differential

resistance tool (App . C , Fig . C-3)

into spline of one side gear.

c.

Put torque wrench on end of

differential resistance tool.

Read the value of torque wrench

as differential gears are

rotated.

9-23

|