| |

TM 10-3930-660-34

8-6. FRONT PLANETARY WHEEL ENDS - REPLACE (Cont’d)

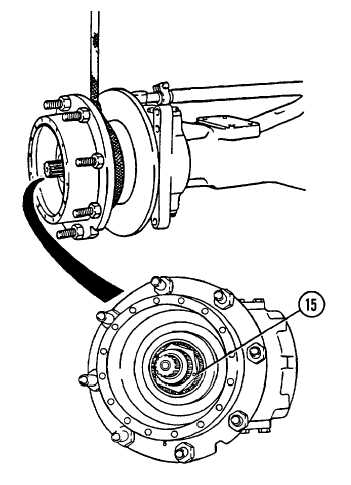

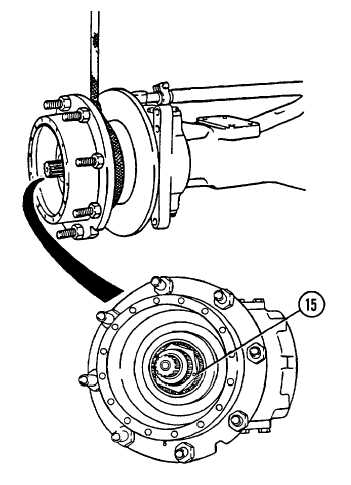

c.

Install planetary ring gear (13). It may be

necessary to turn hub bearing nut (14) to

match hole (A) on back of planetary ring gear

(13). Hub bearing nut (14) may be tightened to

match dowel pin (15) with planetary ring gear,

but torque on hub bearing nut (14) should not

exceed 150 lb. ft.

d.

Install sun gear thrust washer (12), sun gear

(11) and new spindle snap ring (9). Tangs on

thrust washer (12) must engage slots in ring

gear (13).

6.

ASSEMBLE PLANETARY SPIDER.

a.

Apply a thin film of gear lubricating oil to bore

of planetary gear (8). Slide planetary gear (8)

and outer thrust washer (7) onto planetary

pinion shaft (6).

b.

Install new snap ring (5) onto planetary pinion

shaft (6).

c.

Repeat STEPS a and b for second and third

sets of planetary gears (8), thrust washers (7)

and snap rings (5).

7.

INSTALL PLANETARY GEAR ASSEMBLIES.

a.

Remove dirt, grease or moisture from the

mating surfaces of the spider flange and hub

mounting face.

b.

Dry both surfaces.

8-38

|