| |

CAUTION

Inner oil seal (25) and bushing (24) in bore of spindle

(10) could be damaged when sliding spindle past axle

splines. Install spindle carefully to avoid damaging

bushing inner oil seal (25). Failure to do so could cause

premature component failure.

b.

Install spindle (10).

NOTE

Install two shorter capscrews (22) at two top holes and

two capscrews (22) at bottom two holes.

c.

Install ten capscrews (21), four shorter

capscrews (22), and fourteen flatwashers

(23) to secure wheel bearing spindle (10).

Torque capscrews (21 and 22) to 150 lb. ft.

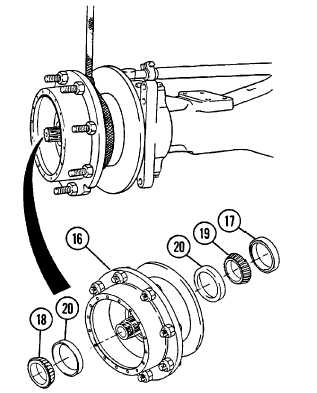

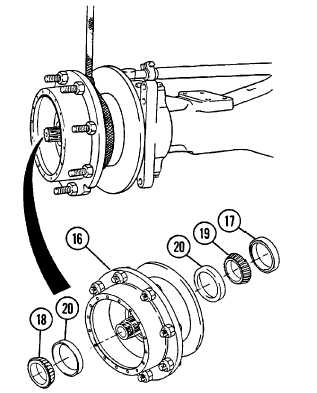

3. INSTALL WHEEL HUB AND DISC ASSEMBLY (16).

a.

Install two bearing cups (20) with a suitable

driving sleeve into wheel hub.

b.

Place wheel hub and disc assembly (16) on

floor or bench with the brake disc up.

c.

Apply a thin film of gear lubricating oil to

inner bearing (19) and install in inner

bearing cup (20).

d.

Install oil seal (17) with a suitable driver.

e. Use a sling and hoist or other suitable lifting

device to support weight of wheel hub and

disc assembly (16).

f. Apply a thin film of gear lubricating oil to

inside diameter of oil seal (17) and to oil seal

journal surface of wheel bearing

spindle (10).

g.

Align wheel hub and disc assembly (16)

with wheel bearing spindle (10). Push

wheel hub and disk assembly (16) onto

spindle (10).

h.

Install outer bearing cone (18) in outer

bearing cup (20).

i.

Install hub bearing nut (14) and draw wheel

hub and disc assembly (16) into position

while rotating wheel hub.

8-36

|