| |

TM10-3930-660-34

8-5.

FRONT DIFFERENTIAL CARRIER ASSEMBLY - REPLACE/REPAIR/ADJUST (Cont’d)

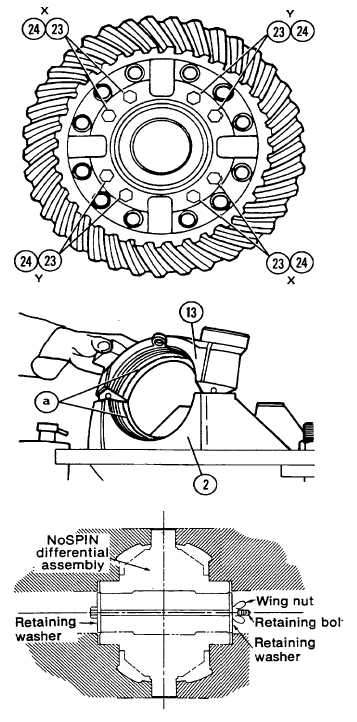

CAUTION

Spacing between four initially installed

capscrews (23) must be even to prevent

uneven pressure on case halves when

torquing. Failure to do so could cause

component failure.

o. Torque four capscrews (23) to

between 60 and 75 lb. ft.

NOTE

Torque capscrews (23) in pairs on

opposing sides of ring gear (22).

p. Install remaining four capscrews

(23) and four flatwashers (24).

Torque capscrews to between 60

and 75 lb. ft.

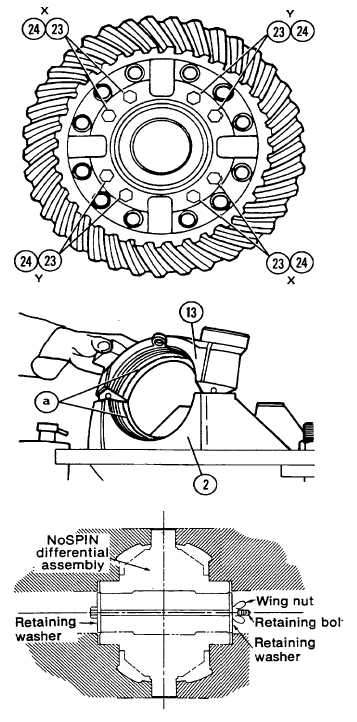

q. Remove no spin retaining bolt,

flatwashers, and wing nut.

NOTE

When installing bearing cups (18), apply

Loctite #277 to bearing bores of

differential carrier (2) legs and

bearing caps (13). Do not apply Loctite

#277 to adjusting ring (15) threads.

8.

INSTALL DIFFERENTIAL AND RING GEAR

ASSEMBLY.

a. Clean and dry bearing cups (18),

bores of differential carrier

(2) legs and bearing caps (13).

b. Apply thin film of gear oil to

inner diameter of the bearing

cups (18) and on both bearing

cones (19 and 20).

c. Apply thin bead of Loctite #277

to bearing bores (a) of differential

carrier (2) legs and bearing

caps (13). Do not apply Loctite

#277 to adjusting ring (15)

threads.

8-25

TM10-3930-660-34

|