| |

TM10-3930-660-34

6-4. STARTER - REPAIR (Cont’d)

INSPECTION

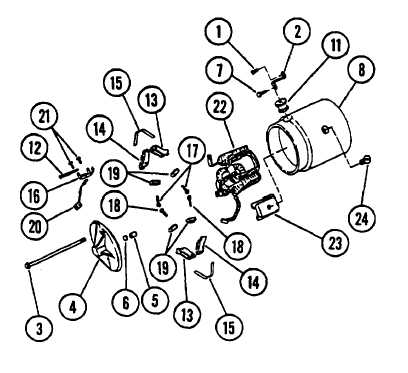

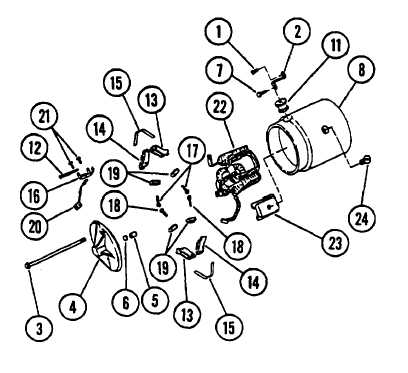

1. BRUSH COMPONENTS.

a. Check brush (19) lengths against

length of new brush. Brushes that

are less than two-thirds the length

of a new brush must be replaced.

b. An oil soaked brush must also be

replaced.

c. Check to ensure that brushes fit

well in holders (13 and 14), but

without binding.

d. Inspect brush springs (15) for

distortion or discoloration.

CAUTION

Do not turn down commutator nor undercut

insulation between commutator bars.

Replace armature if commutator cannot be

restored satisfactorily in STEP 2, below.

2. CHECK CONDITION OF COMMUTATOR, AND

CLEAN, IF NECESSARY, USING NO. 240

GRIT EMERY PAPER.

3. CHECK FOR SHORT CIRCUITS IN ARMATURE

USING A GROWLER AND STEEL STRIP.

a. Rotate armature in growler.

b. Hold steel strip (e.g., hacksaw

blade) across armature slots as

armature rotates. Steel strip will

vibrate as slot between shorted

bars passes under steel strip.

c. If short circuit is detected, check

for build up of copper dust or

other conductive material between

commutator bars.

6-14

|