| |

TM10-3930-660-34

4-6.

TURBO ASSEMBLY - REPAIR (Cont’d)

CAUTION

Be sure scribe marks on diffuser (13)

bearing housing (2) and turbine housing

(3) are properly aligned during

assembly. Failure to properly align

components could result in premature

component failure.

31. BEND LOCK PLATE (12) TABS UP TO

SECURE CAPSCREWS (11).

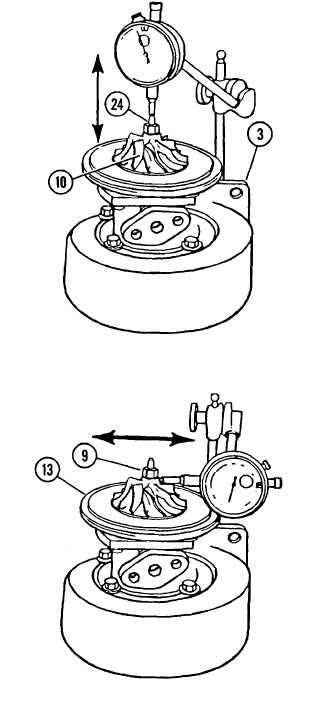

32. MEASURE SHAFT END PLAY.

a. Attach a dial indicator to the

turbine housing (3). Adjust dial

indicator so that plunger is

against shaft (24) end.

b. Set dial indicator to zero.

c. Move shaft (24) and impeller (10)

assembly back and forth and read

end play on dial indicator. If

end play is less than 0.001

inch, or greater than 0.003

inch, disassemble turbocharger,

STEPS 1-19, and check for

problem. Replace defective parts

and assemble, STEPS 1-32.

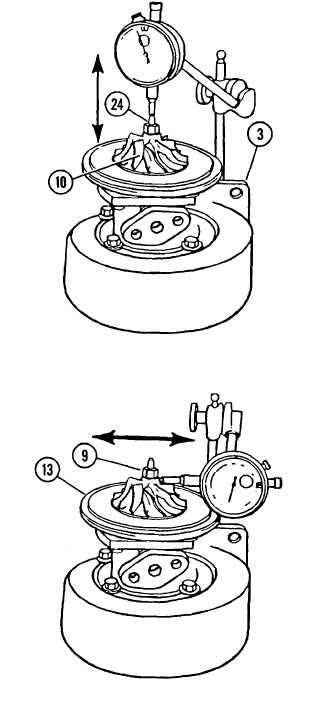

33. MEASURE RADIAL CLEARANCE OF SHAFT

(24).

a. Attach a dial indicator to

turbine housing. Adjust dial

indicator plunger so that plunger

is against end of impeller (13)

between fins and jam nut (9).

b. Set dial indicator to zero.

4-22

|