| |

TM10-3930-660-34

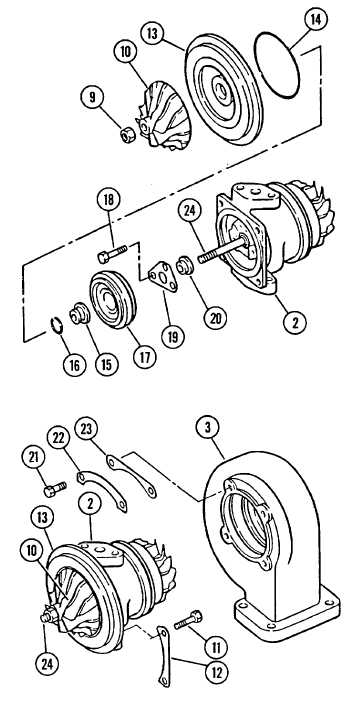

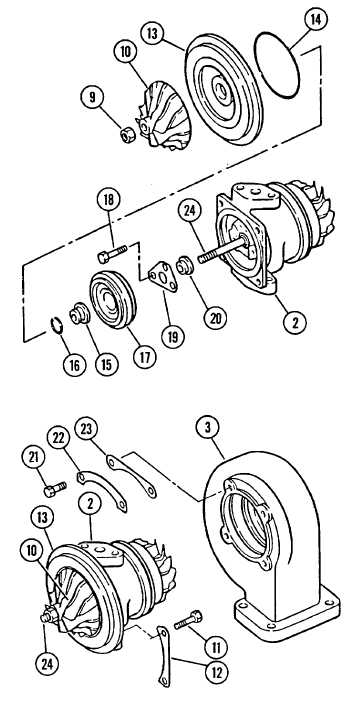

4-6.

TURBOCHARGER ASSEMBLY - REPAIR (Cont’d)

_

CAUTION

Do not allow impeller (10) to turn when

installing locknut (9). Failure to

prevent impeller from turning will

result in improper balance and premature

component failure.

NOTE

Locknut (9) has left-hand threads, be

sure to turn locknut (9) counter-

clockwise when installing.

22. INSTALL NEW LOCKNUT (9) ONTO SHAFT.

TORQUE LOCKNUT (9) TO 120 LB. IN.

23. INSTALL BEARING HOUSING (2),

IMPELLER (10) AND SHAFT (24) INTO

TURBINE HOUSING (3) AS AN ASSEMBLY.

24. ALIGN MATCH MARKS ON BEARING HOUSING

(2) AND TURBINE HOUSING (3) THAT

WERE MADE AT DISASSEMBLY.

NOTE

When installing new capscrews (21), apply

Loctite #767-64 to capscrew (21) threads.

25. APPLY LOCTITE #767-64 TO NEW

CAPSCREW (21) THREADS.

26. INSTALL TWO NEW LOCK PLATES (22), ONE

CLAMPING PLATE (23), AND FOUR NEW

CAPSCREWS (21) INTO TURBINE HOUSING.

27. TORQUE CAPSCREWS (21) TO 100 LB. IN.

28. BEND LOCK PLATE (22) TABS UP TO

SECURE CAPSCREWS (21).

29. INSTALL TWO NEW LOCK PLATES (12) AND

FOUR CAPSCREWS (11) THROUGH BEARING

HOUSING (2) AND INTO DIFFUSER (13).

30. TORQUE CAPSCREWS (11) TO 50 LB. IN.

4-21

|