| |

TM10-3930-660-34

4-6.

TURBOCHARGER ASSEMBLY - REPAIR

This task covers:

a. Disassembly

b. Cleaning

c. Inspection

d. Assembly

Initial Setup

Tools

Materials/Parts

Tool Kit, Automotive Mechanics

Capscrews (18)

Crocus Cloth (App. B, Item 4)

Shop Equipment, Automotive

Engine Lubricating Oil (App. B,

Maintenance, Common #2 Less

Item 26)

Power

Locknut (9)

Lock Plates (12,22)

Equipment Condition

Loctite #767-64 (App. B, Item 46

Turbocharger removed,

Medium Grit Emery Cloth (App. B

TM10-3930-660-20.

Item 5)

Rectangular Ring Seal (6)

Retaining Rings (27, 29)

Seal (14, 16, 26)

Thrust Bearing (19)

DISASSEMBLY

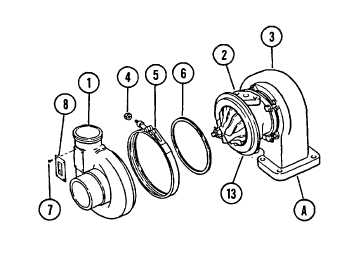

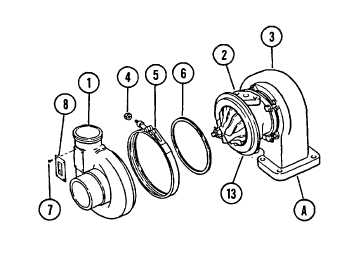

1. MARK COMPRESSOR HOUSING (1), BEARING

HOUSING (2), TURBINE HOUSING (3),

AND DIFFUSER (13), FOR CORRECT PART

ORIENTATION AT ASSEMBLY.

2. PLACE TURBOCHARGER IN A VISE AND

CLAMP BY THE TURBINE HOUSING INLET

FLANGE (A). PLACE SOFT METAL COVERS

OVER VISE JAWS TO PREVENT DAMAGE TO

TURBINE HOUSING (3).

3. LOOSEN NUT (4) ON V-BAND CLAMP (5).

4. REMOVE COMPRESSOR HOUSING (1),

V-BAND CLAMP (5) AND RECTANGULAR

RING SEAL (6). DISCARD RECTANGULAR

RING SEAL (6).

5. IF NECESSARY, REMOVE DATAPLATE (8).

a. Remove four drivescrews (7).

b. Remove dataplate (8).

4-16

|