| |

TM 10-3930-660-34

3-18. CAMSHAFT, CAMSHAFT GEAR, AND CAMSHAFT BUSHING - REPLACE (Cont’d)

DISASSEMBLY

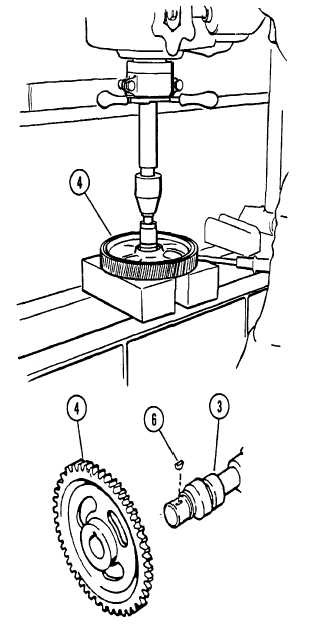

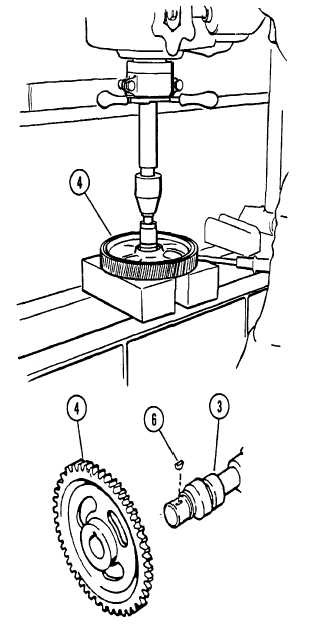

1.

USE A PRESS TO PUSH GEAR (4) FROM

CAMSHAFT (3).

2.

REMOVE KEY (6) FROM CAMSHAFT.

3.

USE CROCUS CLOTH TO REMOVE ALL BURRS

AND SMOOTH ANY ROUGH SURFACES ON THE

CAMSHAFT THAT COULD HAVE BEEN CAUSED

BY GEAR REMOVAL.

CLEANING

See Cleaning Instructions, para. 2-10.

INSPECTION

1.

INSPECT CAMSHAFT BUSHING AND

CAMSHAFT BORES IN CYLINDER BLOCK.

a. Inspect camshaft bushing and camshaft bores

for

burrs, scoring, grooves, and pitting.

b. Measure front camshaft bushing I.D. Acceptable

range is 2.1295 to 2.1314 in.

NOTE

If intermediate and rear camshaft bores have

service bushings installed, the I.D. dimension

must be within the tolerance specified above in

step b.

c. Measure intermediate and rear camshaft bores

I.D. Acceptable bore I.D. range is 2.1295 to

2.1314 in. If bores are worn beyond this

specification, the block must be machined and

service bushings installed, or the block must be

replaced. Refer to Depot level maintenance.

NOTE

If new valve tappets are being installed, the

camshaft and camshaft bushing must be

replaced

3-113

|