| |

TM 10-3930-660-34

3-17. VALVE TAPPETS - REPLACE (Cont’d)

INSPECTION

1.

SEE "INSPECTION INSTRUCTIONS", PARA. 2-11.

2.

INSPECT TAPPETS.

Inspect socket, stem and face for excessive wear

and other damage.

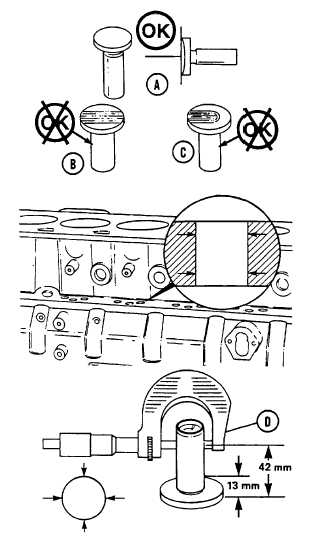

Inspection Point Indication

A

Normal wear

B & C

Abnormal wear,

do not reuse.

3.

MEASURE TAPPET BORES. IF TAPPET BORES

IN CYLINDER BLOCK ARE NOT WITHIN

SPECIFIED TOLERANCE, THE ENGINE MUST

BE REBUILT.

Wear Limit Tolerance

0.630 - 0.632 inch

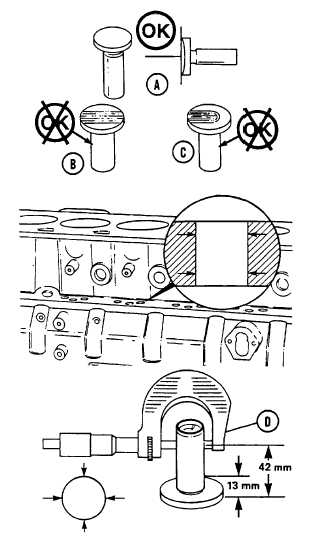

4.

CHECK TAPPET DIMENSIONS.

D (Minimum Diameter) = 0.627 inch

Check tappet diameter in four places: 42 mm from

face, 13 mm from face, and 900 to each

measurement.

INSTALLATION

1.

TURN ENGINE STAND SO CRANKSHAFT (1) IS

FACING UP

CAUTION

Be careful not to drop the tappets (2) into the

bottom of the pistons during tappet installation

as this could damage the pistons.

2.

APPLY LUBRIPLATE 105 TO OUTSIDE

DIAMETER OF TAPPET (2).

3.

USE A MAGNET TO INSTALL TAPPETS (2) INTO

CYLINDER BLOCK (3).

NOTE

If new tappets were installed, a new camshaft

must also be installed.

4.

INSTALL CAMSHAFT, PARA. 3-18.

5.

INSTALL OIL PAN, PARA. 3-20.

3-110

|