| |

TM 10-3930-660-34

3-9. CRANKSHAFT MAIN BEARINGS - REPLACE (Cont’d)

CAUTION

If the crankshaft is turned in the wrong

direction, the bearing tab will be pushed

between the crankshaft and bearing area in

the block. This could cause damage to the

block and the crankshaft.

g.

Slowly

turn

crankshaft

in

the

correct

direction until upper bearing tab is in the

cylinder block notch.

h.

Remove bearing removal/installation tool

from crankshaft oil hole.

i.

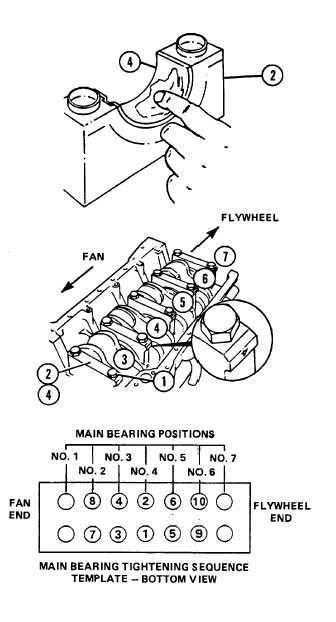

Place lower bearing half (4) into bearing

cap (2) that it was removed from. If a new

bearing is being installed, use the correct

size bearing as determined in STEP 2

above. Apply Lubriplate 105 to inside

surface of bearing half.

j.

Install bearing (4), bearing cap (2) and two

capscrews (1) on bearing bore with the

same number as that stamped on cap, with

number facing towards the oil cooler side of

engine.

k.

After installing each bearing and bearing

cap, tighten capscrews (1) to 37 lb. ft. Do

not tighten capscrews to final torque value

at this time.

l.

Repeat STEPS a through k for the other

main bearings 2 through 5 and thrust

bearing (5) at position number 6.

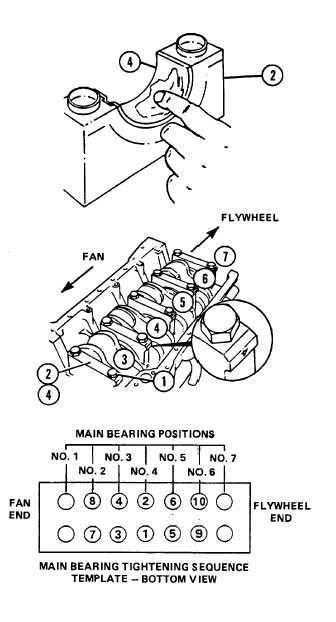

m.

Tighten

capscrews

(1)

evenly

in

the

sequence shown to 44 lb. ft.

n.

Tighten capscrews (1) evenly again in the

sequence shown to 88 lb. ft.

3-74

|