| |

TM 10-3930-660-34

3-9. CRANKSHAFT MAIN BEARINGS - REPLACE (Cont’d)

b.

Clean main bearing surfaces in the cylinder

block and bearing caps with cleaning

solvent P-D-680. Dry surfaces thoroughly

with low pressure compressed air (15 psig

max.).

NOTE

Install bearing halves dry for the following

clearance checks.

c.

Refer to end play data measured earlier in

REMOVAL, STEP 1. If crankshaft end play

is not within 0.005 to 0.010 inch, install a

new, appropriate oversize thrust bearing

(5).

d.

Install a dry upper main bearing half (3)

over the crankshaft journal such that the

bearing tab will fit into the notch in cylinder

block. If used main bearing is being

installed, install upper bearing half in the

same position it was removed from.

e.

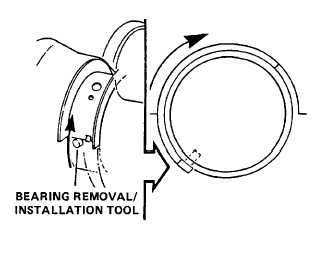

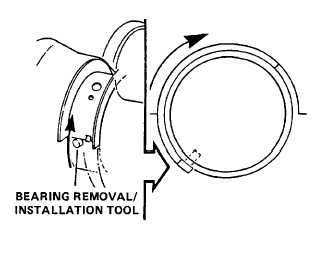

Insert

bearing

removal/installation

tool,

(App. C, Fig. C-7) into bearing journal oil

hole so that it will push against tab end of

bearing.

CAUTION

If the crankshaft is turned in the wrong

direction, the bearing tab will be pushed

between the crankshaft and bearing area in

the block. This could cause damage to the

block and the crankshaft.

f.

Slowly

turn

crankshaft

in

the

correct

direction until upper bearing tab is in the

cylinder block notch.

g.

Remove bearing removal/installation tool

from crankshaft oil hole.

3-70

|