| |

TM 10-3930-660-34

3-8.

CRANKSHAFT - REPLACE/REPAIR

(Cont’d)

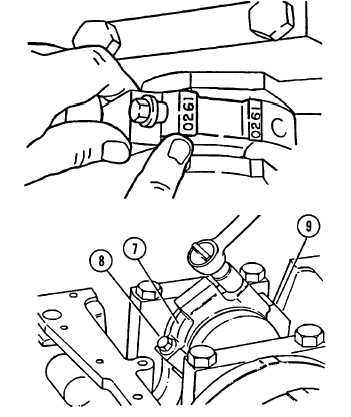

h.

Remove capscrews (8) and connecting rod

caps (7).

i.

Measure plastigage to determine what size

connecting rod bearings to install.

j.

Repeat STEPS a through i for the other five

connecting rods.

6. INSTALL CONNECTING ROD BEARINGS (10 AND 11)

AND CAPS (7).

a.

Turn crankshaft until two connecting rod

bearing journals are bottom center.

b.

Put upper bearing half (10) on connecting rod

(9) with tab in the rod groove.

c.

Put lower bearing half (11) in connecting rod

cap (7) with tab in cap groove.

d.

Apply Lubriplate 105 to inside surfaces of

upper and lower bearing halves.

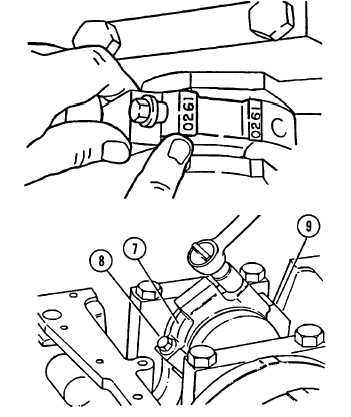

CAUTION

The four digit number stamped on the connecting rod and

the rod cap must match and be facing the oil cooler side of

the engine. Connecting rod and cap are machined as a set

and must be kept that way. Failure to install matched sets

could result in premature engine damage.

e.

Pull piston and connecting rod assembly

against crankshaft journal and install bearing

cap (7) with new capscrews (8). Be sure the

four digit number stamped on the bearing cap

matches

the

number

stamped

on

the

connecting rod and that it is facing towards the

oil cooler end of the engine.

3-65

|