| |

TM 10-3930-660-34

3-8.

CRANKSHAFT - REPLACE/REPAIR

(Cont’d)

i.

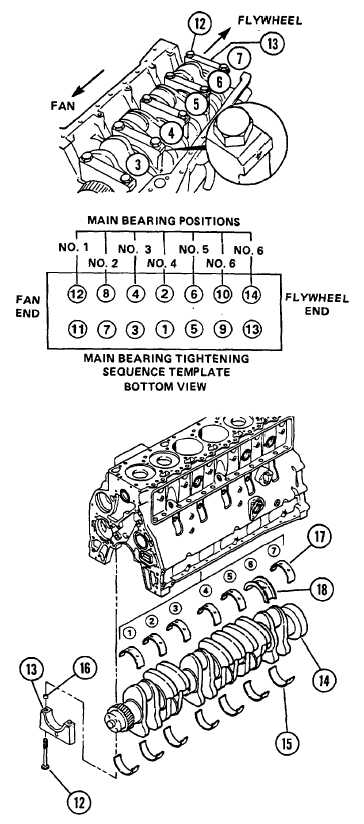

Apply clean lubricating oil to threads of capscrews

(12), then install seven bearing caps (13) and

14 capscrews (12).

NOTE

The number on the bearing cap must correspond to the

number in the cylinder block and it must be facing towards

the oil cooler side of the engine.

j.

The main bearing capscrews (12) must be

tightened evenly in a series of three steps,

and in the sequence shown in this illustration.

The torque values for each step are shown in

this chart.

Step Torque Value

1 44 lb. ft.

2 88 lb. ft.

3 129 lb. ft.

k.

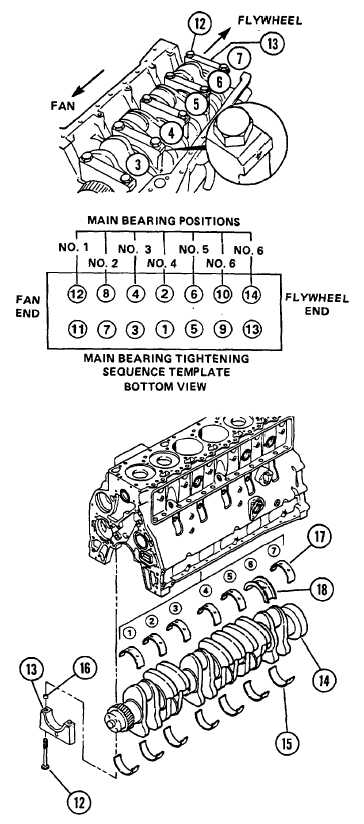

Remove all capscrews (12) and bearing caps (13).

l.

Remove and measure plastigage. Main bearing

clearance must not exceed 0.00474 inch. If

bearing clearance exceeds clearance

measurement, use appropriate oversize

bearings.

m.

Remove lower bearing halves (15) from bearing

caps (13).

3-60

|