| |

TM 10-3930-660-34

3-8.

CRANKSHAFT - REPLACE/REPAIR

(Cont’d)

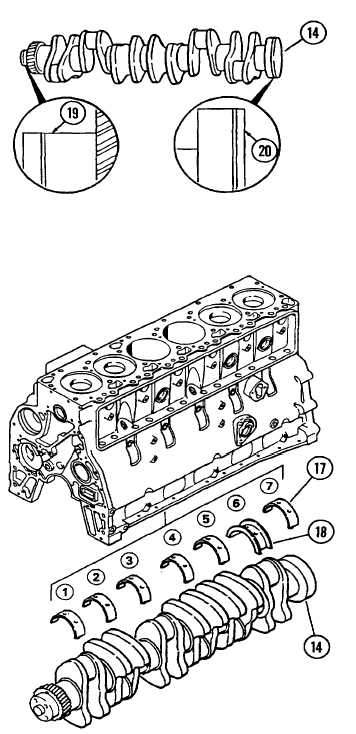

NOTE

Wear sleeves are used only if seal surfaces were damaged

and the surface was machined to allow for sleeve

installation.

2. INSTALL WEAR SLEEVES (19 AND 20).

a.

Install new front wear sleeve (19) over end of

crankshaft (14).

b.

Install new rear wear sleeve (20) over end of

crankshaft (14).

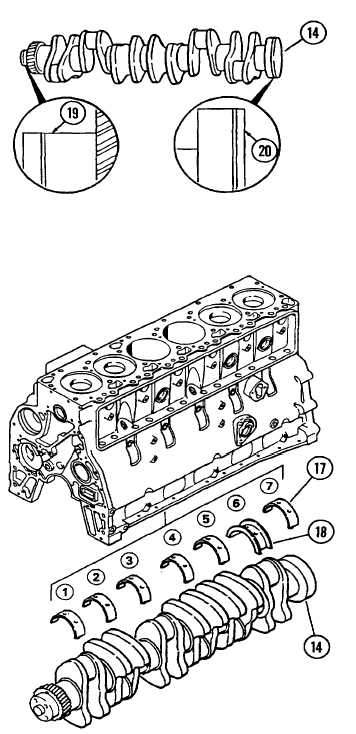

INSTALLATION

1. CLEAN MAIN BEARING SURFACES IN CYLINDER

BLOCK, PARA. 3-9.

NOTE

If the crankshaft journals have been ground, appropriate

oversize bearings will need to be installed.

2. CHECK MAIN BEARING AND THRUST BEARING

CLEARANCE.

NOTE

Install new main bearings dry at this time. Be sure cylinder

block bearing bores, backsides of bearings, and inner

surface of bearing caps are clean and dry.

a.

Align tab of new upper bearing half (17) with

groove in crankshaft bearing bore (cylinder

block), and press bearing half into place.

Perform this procedure for main bearing

positions 1 through 5 and 7.

b.

Install thrust bearing (18) in crankshaft bearing

bore no. 6 with tab in bearing bore groove.

3-58

|