|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

REAR DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0298 00

ASSEMBLY - CONTINUED

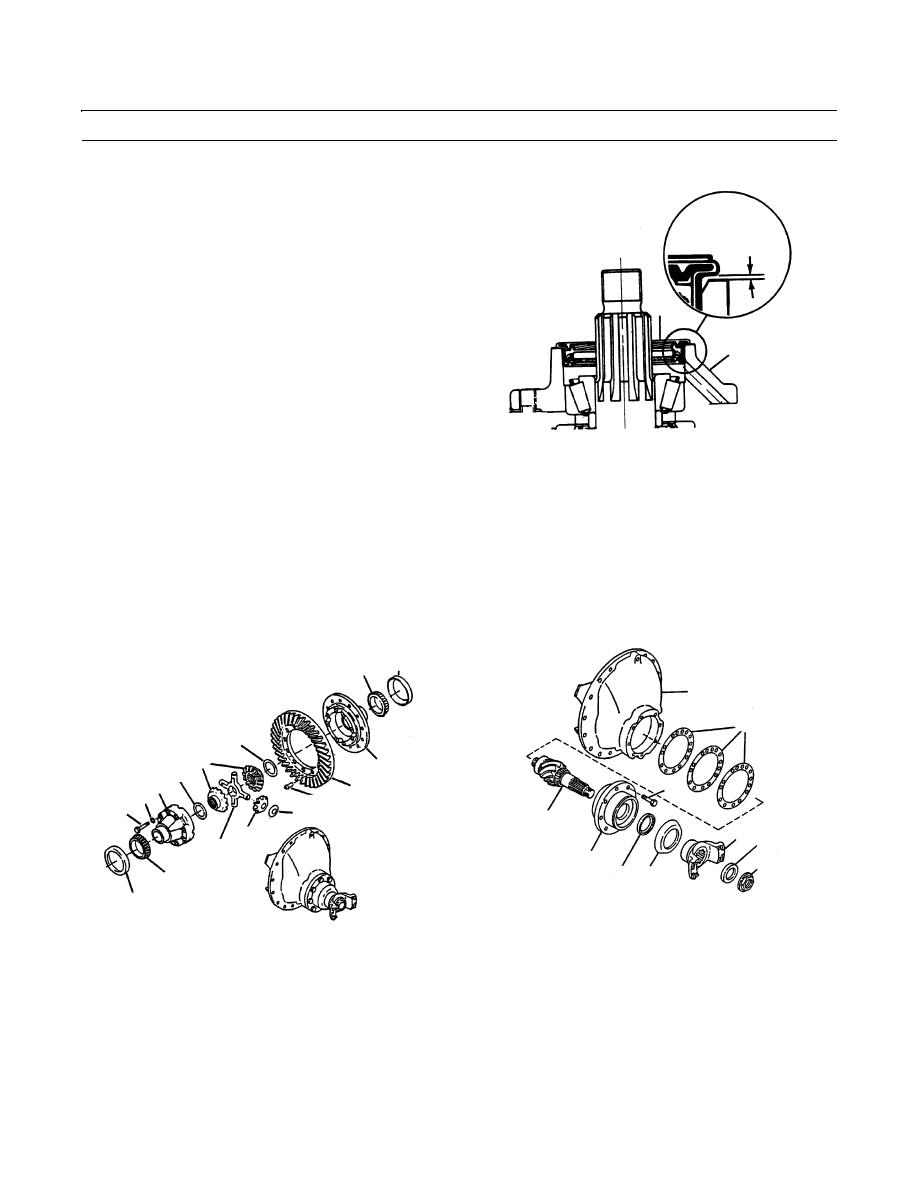

22.

Apply a thin film of clean lubricating oil to inner sur-

face of new pinion oil seal (29).

B

23.

Apply thin film of clean lubricating oil to seal bore in

pinion bearing cage (27).

24.

Use a press or mallet and suitable sleeve to install

29

bevel pinion bearing oil seal (29) into pinion bearing

cage (27) until flange of seal is against bearing cage.

27

25.

Gap (B) of 0.015 to 0.030 in. (0.381 to 0.762 mm) is

normal between new seal (29) and bearing cage (27).

Check gap at several points. The difference between

the largest and smallest gap measurement must not

409-1292

exceed 0.010 in. (0.252 mm).

26.

Install companion yoke (23) with deflector (24), washer (22) and nut (21).

27.

Adjust thickness of shim pack for new bevel pinion (26) and ring gear (8) set. Use a micrometer to measure thickness of

old shim pack (28) removed from under bearing cage (27). Record measurement.

NOTE

If a new bevel pinion and ring gear set is installed, or if the depth of the bevel pinion has to be adjusted, cal-

culate the needed thickness of the shim pack using the following procedure.

28.

Read cone variation number on spigot end of old bevel pinion (26). Record number.

6

9

7

28

14

15

20

14

13

25

8

12

19

11

17

26

23 22

16

18

27

21

29 24

10

409-1286

6

409-1284

0298 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |